Vertical Lift Module

Smarter Storage with Vertical Lift Modules

Fulfilling customer needs can be challenging, but the right automation equipment can help you not only meet those demands but surpass them.

Redefine your storage with our Vertical Lift Modules (VLMs), powered by Modula. These innovative systems are designed to save up to 90% of floor space, streamline inventory management, and improve workflow—all at the push of a button

Everything You Need to Know About Vertical Lift Modules (VLMs)

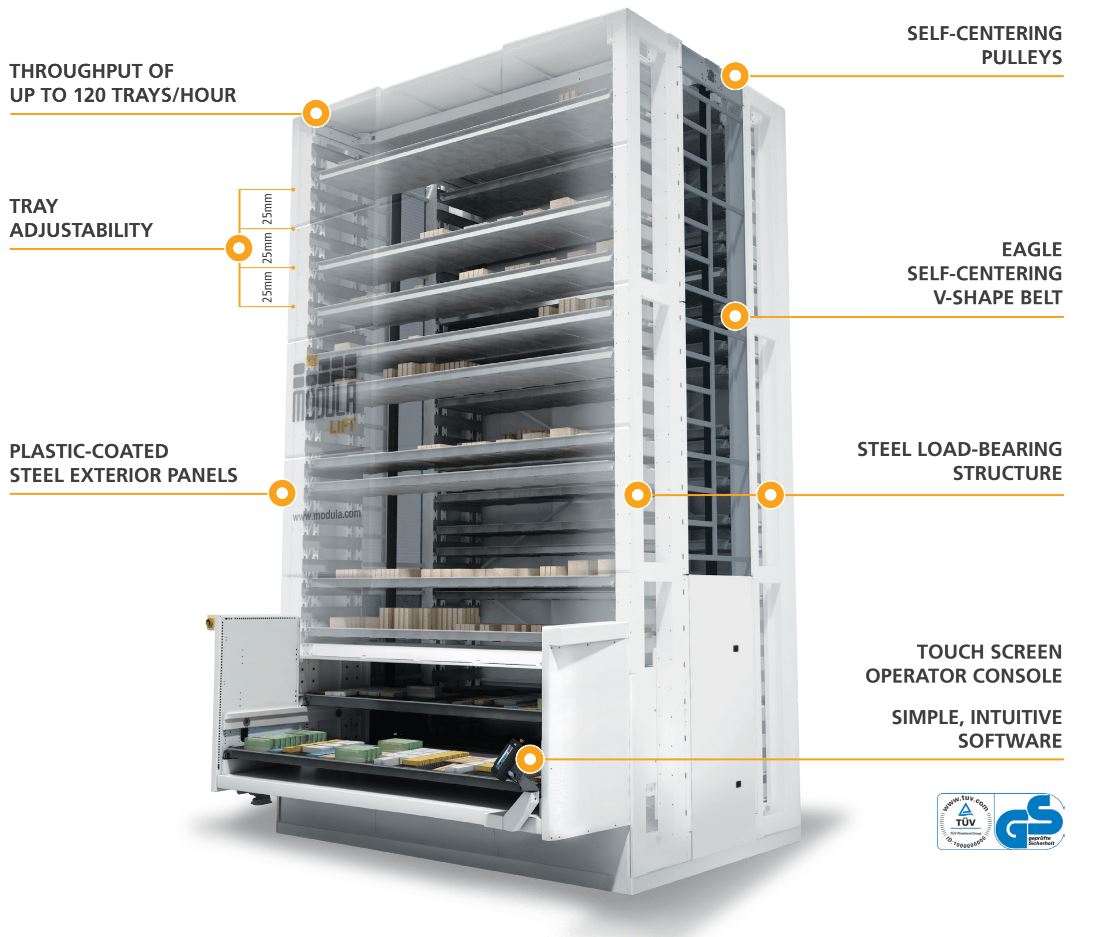

A Vertical Lift Module (VLM) is an automated storage and retrieval system that uses vertically arranged trays within a secure, enclosed unit. It optimizes warehouse space and efficiency by delivering items directly to the operator at an ergonomic height, reducing the need for manual searching and movement.

The cost of a Vertical Lift Module (VLM) depends on factors like size, features, load capacity, and customization. It's best to get a tailored quote based on your specific needs.

Vertical Lift Modules (VLMs) retrieve trays automatically and range from 8 to 98 feet tall, while Vertical Carousels rotate shelves in a loop and range from 7 to 32 feet tall. Vertical Lift Machines suit taller spaces, while carousels are ideal for shorter ceilings and frequent retrieval.

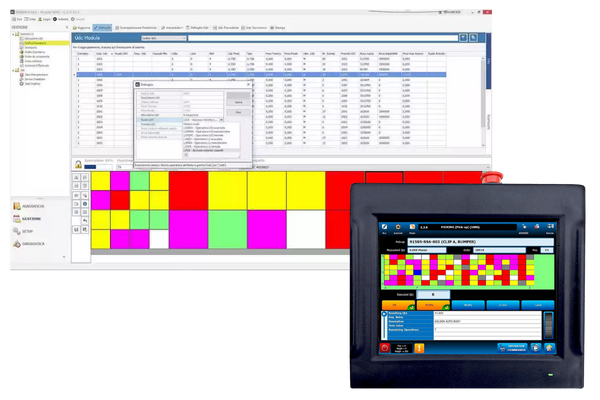

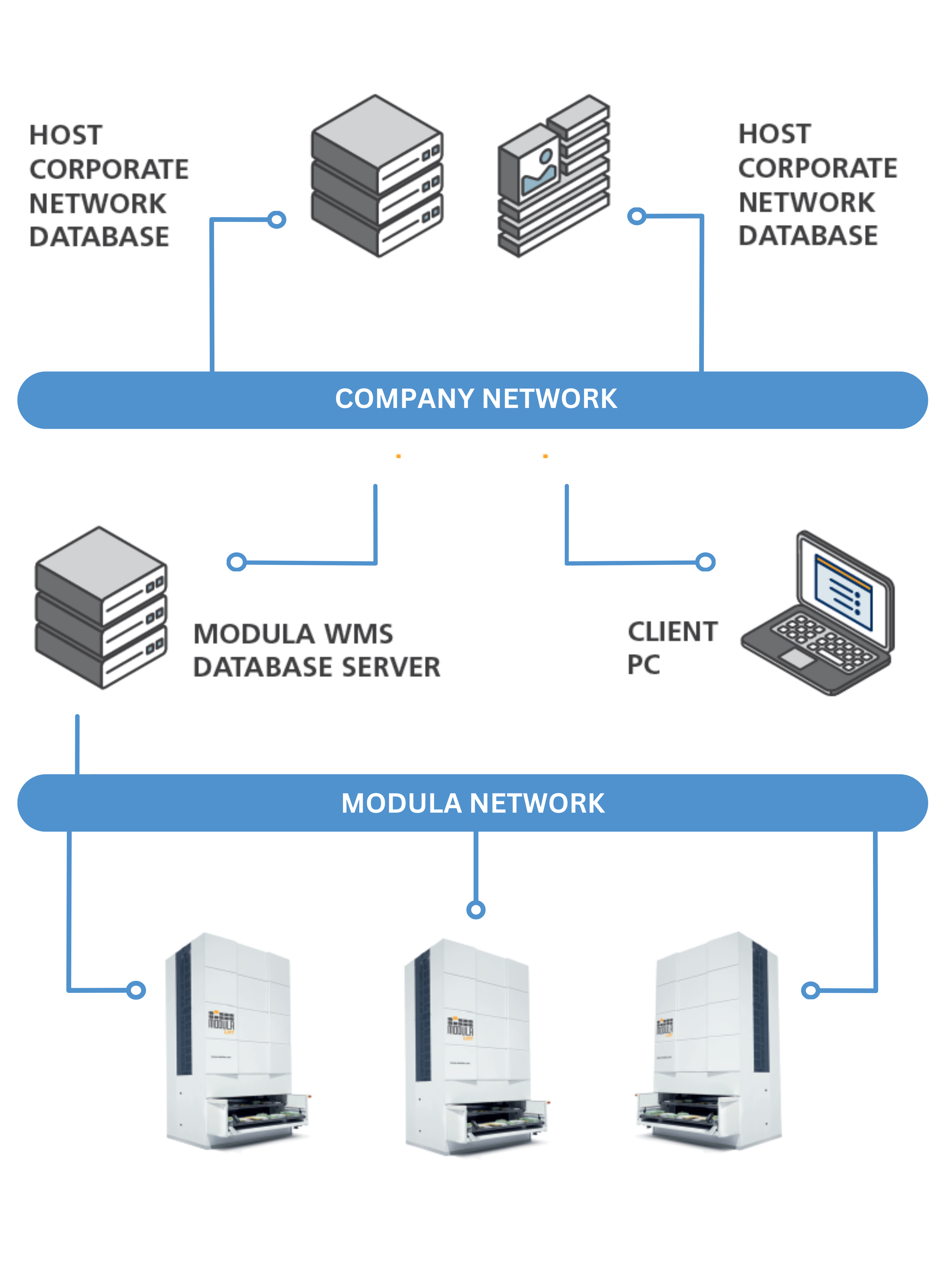

VLM software manages Vertical Lift Modules by controlling inventory, tracking items, and optimizing storage and retrieval processes for improved efficiency and accuracy.

Vertical Lift Modules (VLMs) work by automatically retrieving trays from vertical storage using an elevator mechanism, delivering them to the operator at an ergonomic access point for efficient picking and storage.

Vertical Lift Machines (VLMs) are used for storing and retrieving items in warehouses, factories, and distribution centers, improving space utilization, efficiency, and accuracy in inventory management.

Unlocking the Power of a Vertical Lift Module

- Smart Storage The Modula Vertical Lift Systems stores items in trays within a secure enclosed unit, using the full height of your facility – maximizing your facility’s full vertical potential. By eliminating aisles, the Vertical Lift System increases storage capacity without expanding your footprint.

- Effortless Retrieval The Modula VLM features a user-friendly interface that lets staff easily input item picking details, while the system automatically delivers items at an ergonomic retrieval height – for quicker access and enhanced comfort.

- Goods-to-Person Efficiency The Modula Vertical Lift System follows the Goods-to-Person principle; delivering the right item to the right person at the right height, reducing search time, improving accuracy, and boosting productivity.

Advantages of a Vertical Lift Module

Space Optimization

Our Vertical Lift Machine utilize the available vertical space, reducing the need for expansive floor areas and allowing you to store more items in a smaller footprint.

Increased Productivity

With automated vertical lift module and retrieval, your staff can access items faster, streamlining processes and improving productivity.

Enhanced Accuracy

The VLMs eliminate manual picking errors, ensuring that the right items are retrieved every time, reducing waste, and improving customer satisfaction.

Improved Safety

Greenspace Industrial modula vertical storage are designed with safety in mind. With controlled access and proper training, the risk of workplace accidents is significantly reduced.

Customization

We understand that every business is unique. That’s why our VLMs are customizable to fit your specific storage needs, allowing you to organize your inventory efficiently.

Boost Warehouse Efficiency with Modula Warehouse Management Software (WMS)

Unlock the full potential of your warehouse with Modula WMS and Modula VLM, designed to optimize operations and boost efficiency. Here’s how:

- Seamless Integration

- Boost VLM Performance

- Real-Time Synchronization

- Enhanced Productivity

| Modula WMS easily integrates with your existing ERP and DMS systems to streamline inventory tracking, order fulfillment, picking, and shipping. |

|

Modula WMS automates tasks like receiving, processes faster and more accurate. |

| Enjoy real-time data updates, giving you improved visibility and control over your warehouse operations. |  |

| Together, Modula WMS and Vertical Lift Systems reduce errors, lower costs, and increase efficiency for a more responsive warehouse.

Download Brochure |

MODULA VLM INFORMATIVE LITERATURE

Explore Insightful Realms through Greenspace Industrial’s Informative Brochures on Modula VLM and Advanced Automation Solutions.

Modula One Pick

Modula Climate Control

Modula Fire Suppression

Vertical Lift Module Features and Options

Laser Pointer

- Two-axis laser pointer pinpoints the exact location of an item within a tray

- Enhances production efficiency and boosts operator accuracy

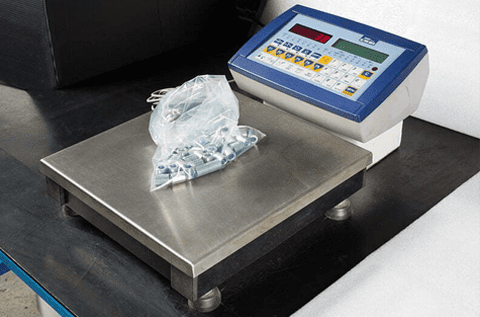

Piece Counting Scale

- Counts items placed on its platform based on the unit weight of identical pieces

- Ideal for recording and storing large quantities of small components

- Enhances order-picking accuracy and speed during the picking and placing phases

Sliding Console

- Supports operators during high-intensity picking tasks by being easily moved closer to the picking point, streamlining the operation for greater efficiency

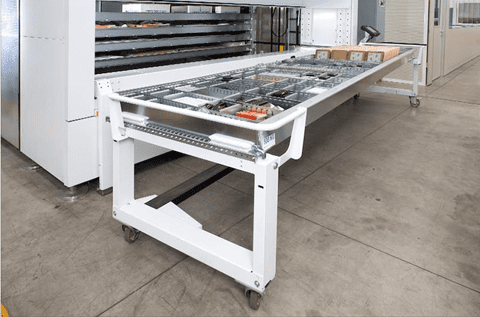

Removable Tray Cart

- Allows operators to extract entire trays from the VLM for transportation

- Ideal for handling heavy loads (up to 1,100 pounds or 500 kg)

Alphanumeric LED Bar

- Displays important information about a picking or placing operation

- Helps operators quickly locate items, boosting productivity in order picking

Partitions & Dividers

- Helps organize materials within trays – reposition to create compartments of various sizes

- Side panels can extend to increase compartment volume or prevent bulky items from spilling

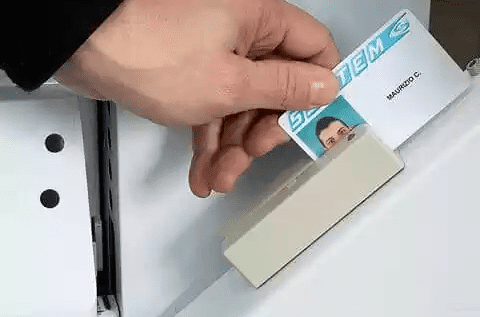

Badge Reader

- Badge reader provides an alternative to username and password login

- Restricts access to unauthorized users by allowing operators to use their personal badges for secure machine access

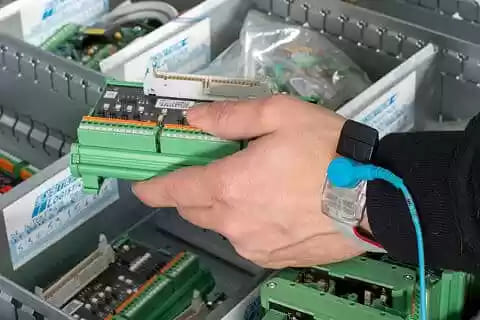

ESD Protection

- Safeguards components from electrostatic discharges by grounding the incoming tray before reaching the operator

Put to Light

- Allows operators to process more order lines simultaneously

- Enables the creation of multiple picking zones, with orders being processed in parallel for greater efficiency

Automatic Door

- Enhances security by keeping stored materials inaccessible when the machine is off or unattended

- Reduces noise, increases operator safety, and prevents pollutants from entering

Dual Tray Delivery

- Two trays can be lowered simultaneously to enhance efficiency in the order picking process.

Energy Saver

- Inverter that captures energy from the VLM’s movement, converting kinetic energy into electricity and feeding it back into the grid

- Cuts energy costs by up to 40%

Enhance Your Workflow with Modula's Advanced Robotic Integration Solutions

Modula’s robotic integration solutions bring automation to the next level by seamlessly combining Vertical Lift Modules (VLM) with advanced robotics. These integrations are designed to optimize workflows, reduce manual labor, and improve accuracy across industries. Whether it’s robotic arms for picking or automated guided vehicles (AGVs) for transport, Modula offers tailored solutions to enhance productivity and streamline operations. Discover how robotics can revolutionize your material handling processes.

Greenspace News

Stay Updated on Innovations & Industry Trends

CONTACT US TO GET STARTED

Your privacy is guaranteed. Your information will not be shared with 3rd party data collections. By submitting this form, you consent to receive electronic communications from Greenspace Industrial.