In an era defined by technological innovation, warehouse automation has emerged as a key driver of efficiency and productivity. At Greenspace Industrial, we are committed to leveraging the latest advancements in automation technology to revolutionize warehouse operations. Our focus on Automated Robotics is aimed at providing businesses with cutting-edge solutions that optimize efficiency, streamline operations, and drive growth.

What is Automated Robotics?

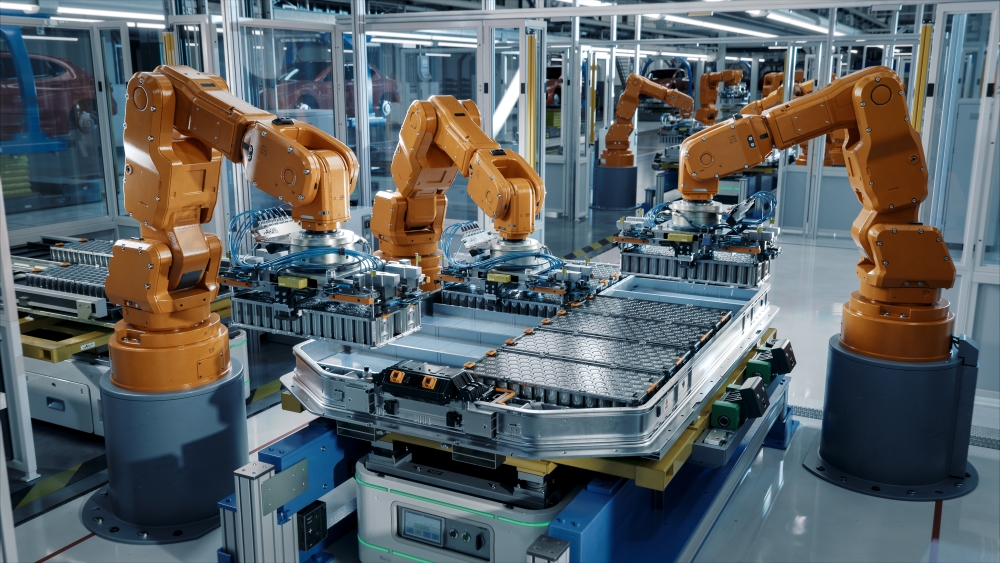

Automated Robotics refers to the use of robotic systems equipped with advanced sensors, actuators, and artificial intelligence (AI) to perform various tasks autonomously or with minimal human intervention. These robots are designed to execute repetitive, labor-intensive tasks with precision and efficiency, thereby enhancing productivity and reducing operational costs.

The Impact of Warehouse Automation

The adoption of warehouse automation, including technologies like Automated Robotics, has had a profound impact on the industry, revolutionizing traditional warehouse operations. One of the most significant benefits is the dramatic increase in operational efficiency. By automating repetitive tasks such as picking, packing, and sorting, businesses can achieve higher throughput rates and reduced cycle times. This increased efficiency translates to cost savings and improved productivity, allowing companies to fulfill orders faster and more accurately than ever before.

Furthermore, warehouse automation has also led to notable improvements in safety within warehouse environments. With Automated Robotics handling hazardous or strenuous tasks, the risk of workplace injuries has been significantly mitigated. Human workers are no longer required to perform physically demanding tasks, reducing the likelihood of accidents and creating a safer working environment overall. This improved safety not only protects the well-being of warehouse staff but also helps companies avoid costly workplace incidents and liabilities. Overall, the impact of warehouse automation on operational efficiency and safety underscores its importance in modern warehouse management strategies.

How Automated Robotics Works

Automated Robotics systems operate through a combination of sophisticated hardware and intelligent software. These systems are equipped with sensors, actuators, and onboard computers that enable them to perceive their environment, make decisions, and execute tasks autonomously. The sensors provide real-time data about the robot’s surroundings, including obstacles, objects, and other equipment in the warehouse. Using this information, the robot’s AI algorithms generate a map of the environment and determine the most efficient path to navigate from one point to another.

Once the robot reaches its destination, it uses its actuators to manipulate objects or perform specific tasks, such as picking items from shelves, placing them in bins, or transporting them to designated locations. The onboard computers coordinate these actions, ensuring smooth operation and precise execution of tasks. Additionally, Automated Robotics systems often incorporate machine learning algorithms that allow them to adapt and optimize their performance over time based on feedback from their interactions with the environment. This continuous learning process enables the robots to become more efficient and effective in their tasks, further enhancing warehouse productivity.

Applications of Automated Robotics

Automated Robotics find versatile applications in warehouse operations, enhancing efficiency and productivity across various tasks:

- Picking and Packing

Automated Robotics excel in the picking and packing process by swiftly and accurately retrieving items from storage locations and packaging them for shipment. Equipped with advanced sensors and AI algorithms, robots can identify and handle a wide range of products with precision, minimizing errors and maximizing throughput.

- Sorting and Shipping

In the sorting and shipping stage, Automated Robotics play a crucial role in streamlining the process of categorizing and routing items for delivery. By automating sorting tasks based on predefined criteria such as destination, size, or weight, robots ensure efficient and timely order fulfillment, reducing processing times and improving customer satisfaction.

- Inventory Management

Automated Robotics revolutionize inventory management by providing real-time visibility and control over stock levels. Robots equipped with RFID scanners and barcode readers can autonomously perform inventory counts, track item locations, and manage stock replenishment, enabling warehouses to maintain optimal inventory levels and minimize stockouts.

- Material Handling

Material handling tasks, such as loading and unloading goods, transporting items within the warehouse, and palletizing shipments, are seamlessly executed by Automated Robotics. With their ability to handle heavy loads and navigate complex warehouse environments, robots streamline material flow and optimize warehouse layout, contributing to overall operational efficiency.

Integrating Automated Robotics into Warehouses

Integrating Automated Robotics into warehouse operations requires careful planning and implementation. Greenspace Industrial offers comprehensive solutions for integrating robotics into existing warehouse infrastructure, ensuring seamless operation and maximum efficiency.

Future Trends in Automated Robotics

- AI Integration: Enhanced with advanced AI, robots learn, adapt, and make real-time decisions, boosting flexibility and task complexity handling.

- Collaborative Robotics: Cobots work alongside humans, equipped with safety features for shared environments, offering flexibility while prioritizing safety.

- IoT Integration: Real-time monitoring and communication between machines and sensors optimize maintenance and operational efficiency.

- AR and VR Applications: AR provides insights and guidance, while VR offers training simulations, improving productivity and reducing errors.

- Enhanced Safety Features: Advanced sensors and collision avoidance systems, coupled with softer materials, minimize risks during human-robot interaction.

- Cloud-based Robotics: Centralized control and coordination through cloud platforms facilitate scalability and adaptability across locations.

In conclusion, Automated Robotics stands as a transformative technology reshaping warehouse operations. Through automation, businesses can attain unparalleled efficiency, productivity, and competitiveness in today’s dynamic marketplace. At Greenspace Industrial, we are dedicated to pioneering these advancements, offering cutting-edge solutions that empower businesses to optimize their operations and thrive in the modern era.