As the leading Warehouse Automation Company in Canada, we at Greenspace Industrial understand that in today’s fast-paced industrial environment, speed, precision, and efficiency are critical for any warehouse operation. Manual storage and retrieval systems often struggle to meet the increasing demands for faster order fulfillment and better inventory management. This is where Automated Storage and Retrieval Systems (ASRS), including Automated Pallet Storage and Retrieval Systems, come into play, offering warehouses a competitive edge by automating storage processes, minimizing errors, and enhancing productivity.

ASRS solutions offer versatility for various industries, from handling pallets to storing small goods. Whether it’s large distribution centers or e-commerce operations, these systems are becoming increasingly popular in global markets, including ASRS systems in Canada. In this blog, we’ll dive into the benefits of Automated Storage and Retrieval Systems, explore different types like Pallet Load ASRS and Mini Load ASRS Systems, and highlight why they are essential for modern warehouses.

What Are Automated Storage and Retrieval Systems (ASRS)?

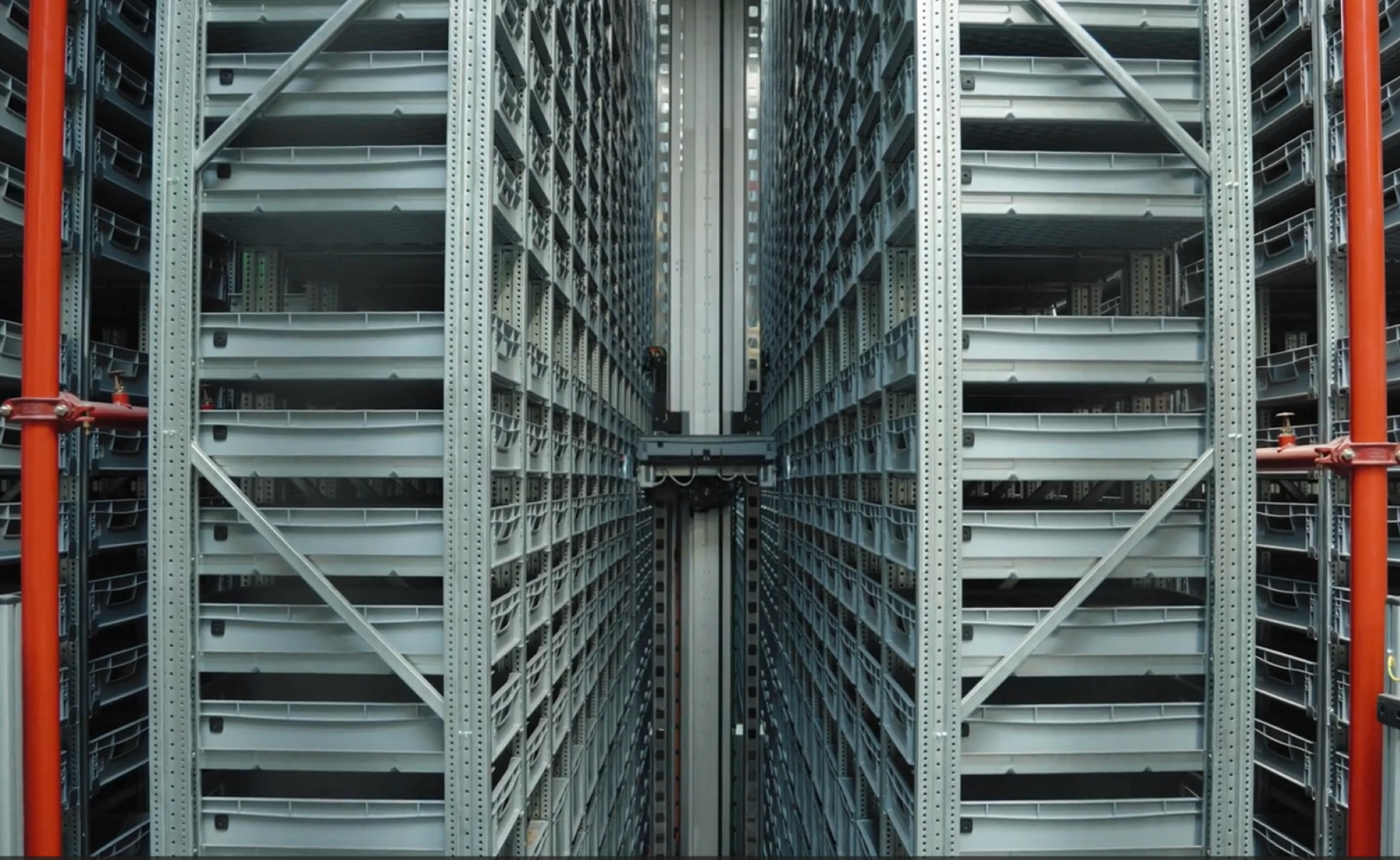

ASRS refers to a warehouse technology designed to automate the storage and retrieval of goods, reducing the need for manual labor. These systems use automated cranes, shuttles, conveyors, and software to efficiently store and retrieve inventory with minimal human intervention. The primary goal is to increase speed and accuracy while optimizing space.

Several forms of ASRS exist. Pallet Load ASRS focuses on moving large palletized goods, while Mini Load ASRS Systems are ideal for handling smaller items or individual cartons. This flexibility allows ASRS to be tailored to the specific needs of different businesses, from large warehouses to smaller fulfillment centers.

How ASRS Transforms Warehouse Operations

Implementing the ASRS system warehouse brings a significant transformation to your warehouse management. Traditional manual operations are time-consuming and prone to errors, whereas ASRS improves both speed and precision. Automated systems allow for faster processing of orders and real-time tracking of inventory, ensuring that businesses can meet tight deadlines without compromising on quality.

In addition to faster workflows, ASRS reduces the dependency on manual labor, which helps warehouses mitigate staffing challenges, particularly during peak seasons. The ability to store items vertically also maximizes available space, reducing the need for warehouse expansion.

Key Benefits of ASRS Systems for Modern Warehouses

Increased Efficiency

ASRS systems enable faster retrieval and storage, reducing lead times and ensuring that customer orders are fulfilled without delay. Automation also improves the accuracy of operations, virtually eliminating human error.

Optimized Space Utilization

Warehouses that implement ASRS can store more products in less space by taking advantage of vertical storage. This is particularly beneficial for warehouses with limited floor space, where expanding horizontally would be costly or impractical.

Lower Operating Costs

By automating key processes, ASRS systems reduce the need for large labor forces, saving on staffing costs. Additionally, fewer errors in storage and retrieval lead to fewer product losses and operational disruptions, further cutting expenses.

Environmental Benefits of ASRS Systems

ASRS systems contribute to sustainability by improving energy efficiency and reducing waste. Automated processes are optimized to minimize the time and energy required to move goods, lowering the overall carbon footprint. Additionally, by reducing the need for large facilities, ASRS helps companies minimize their environmental impact through better space management.

Applications of ASRS in Different Industries

The versatility of ASRS makes it a valuable solution across multiple industries:

E-commerce

Rapid growth in online shopping has led to increased demand for automated systems that can handle high order volumes efficiently.

Food & Beverage

ASRS ensures the freshness of perishable goods by streamlining the storage and retrieval process.

Pharmaceuticals

With the need for precision and traceability, ASRS helps pharmaceutical companies manage inventory with greater accuracy.

ASRS System in Canada: A Growing Trend

Automation is becoming increasingly popular in Canada as companies seek to improve operational efficiency and remain competitive in the global market. Many warehouses are adopting the ASRS system in Canada to enhance order fulfillment processes, particularly in high-demand sectors like e-commerce and manufacturing. Additionally, government incentives and investments in technology are encouraging the adoption of automated solutions, further driving the growth of ASRS in the region.

Types of ASRS Solutions for Warehouses

Mini Load ASRS System

Designed for smaller items, the Mini Load ASRS System is ideal for warehouses that handle lightweight products or small components. These systems are common in the pharmaceutical, electronics, and e-commerce sectors, where rapid and accurate picking of individual items is crucial.

Pallet Load ASRS / Unit Load ASRS

Focused specifically on pallet-based storage and retrieval, Pallet Load ASRS /Unit Load ASRS ensures smooth movement and organization of heavy pallets, minimizing manual handling and improving safety.

How Pallet Load ASRS Improves Safety in Warehouses

Workplace safety is a major concern for warehouses, particularly those that handle heavy pallets or operate forklifts. Pallet Load ASRS helps reduce the risks associated with manual handling by automating the movement of heavy goods. By eliminating the need for forklifts in certain operations, these systems minimize accidents and create a safer working environment for employees.

Mini Load ASRS System: Ideal for High-Density Storage

A mini-load ASRS system offers the perfect solution for warehouses handling smaller items. These systems are designed to store and retrieve small products efficiently, making them ideal for industries that require high-density storage. In addition to saving space, Mini Load ASRS Systems ensure quick and accurate picking, reducing product damage and improving order accuracy.

Scalability and Flexibility of Modern ASRS Systems

One of the biggest advantages of ASRS systems is their scalability. Whether a business needs to expand its storage capacity or adapt to seasonal fluctuations, ASRS solutions can be easily modified to meet changing demands. These systems are also flexible enough to integrate with other warehouse management systems, providing a seamless workflow across different operations.

Challenges and Considerations Before Implementing ASRS

While the benefits of ASRS are numerous, companies should also consider potential challenges. The initial investment in automated systems can be high, and regular maintenance is essential to ensure smooth operations. Additionally, staff must be trained to use and manage the new technology effectively. Working with experienced providers can help businesses overcome these challenges and successfully transition to automation.

Choosing the Right ASRS System for Your Warehouse

Selecting the right ASRS solution depends on several factors, including the warehouse size, the type of goods being handled, and the volume of operations. For larger facilities dealing with heavy products, Unit Load ASRS may be the best option. Smaller warehouses or those handling individual items may benefit more from Mini Load ASRS Systems. Consulting with ASRS providers can help companies choose the system that aligns with their specific needs.

Conclusion

At Greenspace Industrial, being the top Warehouse Automation Company in Canada; we know that in today’s competitive market, Automated Pallet Storage and Retrieval Systems are essential for modern warehouses looking to enhance efficiency, reduce costs, and improve safety. Whether it’s managing pallets with Pallet Load ASRS or optimizing small product storage with Mini Load ASRS Systems, these technologies offer unparalleled benefits for warehouses across industries. With automation trends growing globally, especially in regions like Canada; ASRS systems are becoming crucial for businesses that want to stay ahead. Investing in these solutions ensures long-term operational excellence and a competitive edge in an ever-evolving industry.