Welcome to Greenspace Industrial, where innovation meets efficiency in the world of warehouse management. In today’s rapid business environment, optimizing your warehouse operations is more crucial than ever. With the rise of e-commerce and the increasing demand for faster delivery times, businesses are constantly seeking ways to enhance productivity and streamline their processes. Warehouse optimization is the key to achieving these goals and staying competitive in the market.

Understanding Warehouse Optimization

Warehouse optimization refers to the process of maximizing efficiency and productivity within a warehouse facility. It involves implementing strategies and utilizing technology to improve inventory management, reduce operational costs, and enhance overall workflow. By optimizing your warehouse operations, you can minimize errors, eliminate bottlenecks, and ensure that goods are stored, picked, and shipped in the most efficient manner possible.

Why Optimize Warehouse Operations

In today’s competitive business landscape, optimizing warehouse operations isn’t just a luxury; it’s a necessity. With consumer expectations continuously evolving and the demand for faster delivery times increasing, businesses must find ways to streamline their operations and stay ahead of the curve. Warehouse optimization offers a solution to this challenge by providing companies with the tools and strategies they need to maximize efficiency, reduce costs, and improve overall performance.

By implementing warehouse optimization solutions, businesses can address common pain points such as inventory management inefficiencies, order processing delays, and labor shortages. Whether it’s through the adoption of automated storage and retrieval systems, the optimization of picking routes, or the implementation of real-time inventory tracking technologies, companies can transform their warehouses into highly efficient and responsive facilities. Ultimately, by optimizing their warehouse operations, businesses can not only meet the demands of today’s fast-paced market but also position themselves for long-term success and growth.

Warehouse Optimization Solutions at Greenspace Industrial

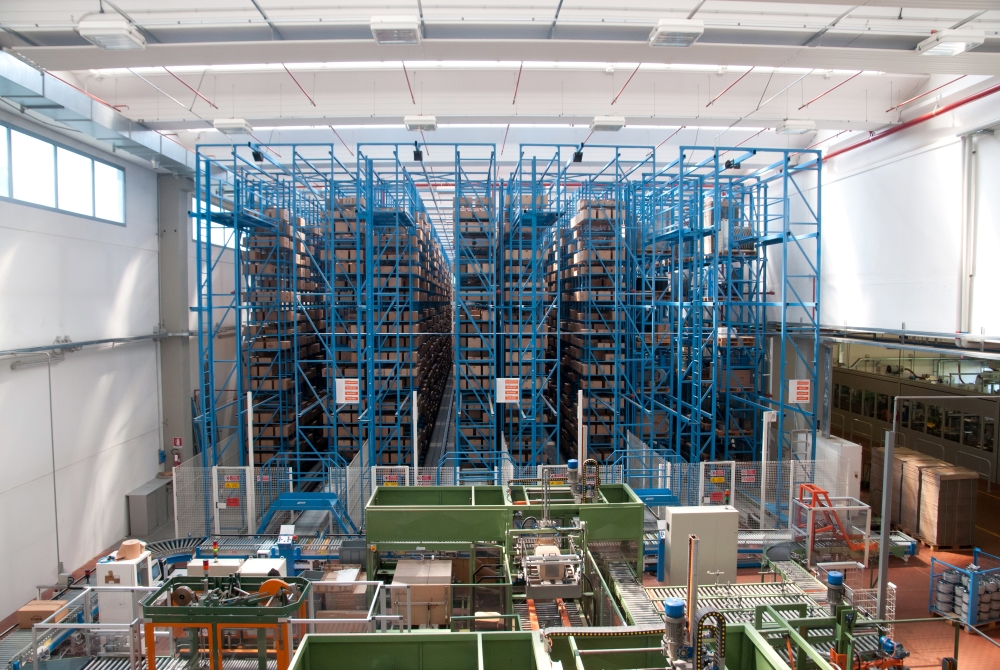

At Greenspace Industrial, we are dedicated to providing cutting-edge warehouse optimization solutions tailored to meet the unique needs of our clients. Our Automated Storage and Retrieval Systems (ASRS) offer a seamless approach to inventory management by automating the storage and retrieval process. With features such as dynamic slotting and real-time inventory tracking, our ASRS solutions enable businesses to maximize space utilization, reduce picking times, and enhance overall efficiency. Additionally, our Vertical Lift Modules (VLM) provide a space-saving solution for warehouses with limited floor space. By utilizing vertical space, our VLM systems optimize storage capacity while minimizing the footprint of your facility, allowing for faster retrieval times and improved organization.

Furthermore, Greenspace Industrial offers a comprehensive suite of warehouse automation solutions to streamline operations and increase productivity. From conveyor systems and sortation equipment to robotic picking and packing solutions, we have the expertise and technology to automate your warehouse processes effectively. Our team works closely with clients to understand their specific requirements and tailor solutions that align with their business goals. With Greenspace Industrial as your partner, you can optimize your warehouse operations, reduce costs, and drive greater efficiency in your day-to-day activities.

Automated Storage and Retrieval Systems (ASRS)

Our ASRS solutions are designed to automate the storage and retrieval of inventory, allowing you to maximize space utilization and minimize picking times. With advanced features such as dynamic slotting and real-time inventory tracking, our ASRS systems can help you optimize your warehouse layout and streamline your order fulfillment processes.

Vertical Lift Modules (VLM)

Our Vertical Lift Modules (VLM) are ideal for warehouses with limited floor space. These compact storage systems utilize vertical space to maximize storage capacity while minimizing the footprint of your warehouse. With fast retrieval times and customizable configurations, our VLM solutions are perfect for businesses looking to optimize their storage space and improve efficiency.

In addition to ASRS and VLM systems, we offer a variety of other warehouse automation solutions to help streamline your operations. From conveyor systems and sortation equipment to robotic picking and packing solutions, we have everything you need to automate your warehouse processes and increase productivity.

Implementing Warehouse Optimization Strategies

1. Conduct Comprehensive Analysis

- Identification of Inefficiencies: Analyze current warehouse processes to pinpoint areas for improvement.

- Evaluation of Operations: Assess factors such as workflow, inventory management, and picking procedures.

2. Prioritize Optimization Opportunities

- Impact Assessment: Evaluate potential improvements based on their effect on efficiency, cost savings, and feasibility.

- Ranking of Strategies: Prioritize optimization initiatives according to their potential benefits and ease of implementation.

3. Implement Automated Solutions

- Automation Integration: Integrate Automated Storage and Retrieval Systems (ASRS), Vertical Lift Modules (VLM), and conveyor systems to streamline operations.

- Enhanced Efficiency: Automate repetitive tasks such as picking, packing, and inventory management to improve efficiency.

4. Optimize Warehouse Layout

- Space Utilization: Arrange storage areas to maximize space utilization and minimize unnecessary movements.

- Workflow Optimization: Design workflows to facilitate smooth movement of goods and reduce bottlenecks.

5. Invest in Inventory Management Technology

- Software Integration: Implement inventory management software and technology solutions to enhance accuracy and visibility.

- Real-time Tracking: Utilize technology to monitor inventory levels and locations in real-time, improving inventory management efficiency.

6. Provide Training and Support

- Employee Education: Train warehouse staff on new processes and technologies to ensure smooth adoption.

- Ongoing Support: Offer continuous support and guidance to employees as they adjust to changes.

7. Monitor Performance Metrics

- Key Performance Indicators (KPIs): Establish KPIs such as order fulfillment time, inventory accuracy, and labor productivity.

- Performance Tracking: Continuously monitor and analyze performance metrics to assess the effectiveness of optimization efforts.

8. Review and Adjust Strategies

- Continuous Evaluation: Regularly review warehouse optimization strategies to identify areas for improvement.

- Adaptation to Change: Adjust strategies based on evolving business needs, technological advancements, and industry trends.

9. Foster a Culture of Continuous Improvement

- Encourage Innovation: Cultivate a workplace culture that values innovation and encourages employees to contribute ideas for optimization.

- Feedback Mechanisms: Implement feedback mechanisms to gather suggestions from warehouse staff and stakeholders.

10. Collaborate with Suppliers and Partners

- Supply Chain Optimization: Collaborate with suppliers and partners to implement collaborative planning and forecasting processes.

- Shared Optimization Goals: Work together to optimize supply chain processes, reducing lead times and improving efficiency.

Leveraging Technology for Warehouse Optimization

Technology plays a crucial role in warehouse optimization, providing tools and solutions to help businesses streamline their operations and improve productivity. From advanced inventory management systems to warehouse management software, there are a variety of technologies available to help you optimize your warehouse operations. By leveraging technology, you can automate routine tasks, improve inventory accuracy, and enhance overall efficiency in your warehouse.

Overcoming Challenges in Warehouse Optimization

While warehouse optimization offers numerous benefits, it also comes with its own set of challenges. One common challenge is resistance to change, as employees may be hesitant to adopt new technologies or processes. To overcome this challenge, it’s important to involve employees in the optimization process from the beginning, providing training and support to help them adapt to the changes. Additionally, it’s important to carefully plan and execute any changes to minimize disruption to your operations and ensure a smooth transition to the new optimized processes.

Measuring Success and Continuous Improvement

Once you’ve implemented warehouse optimization strategies, it’s important to regularly measure your success and continue to seek ways to improve. Key performance indicators (KPIs) such as order fulfillment time, inventory accuracy, and labor productivity can help you track the effectiveness of your optimization efforts and identify areas for further improvement. By continuously monitoring your performance and making adjustments as needed, you can ensure that your warehouse operations remain optimized and efficient over time.

The Future of Warehouse Optimization

As technology continues to advance and consumer expectations evolve, the future of warehouse optimization holds exciting possibilities. From the adoption of artificial intelligence and machine learning to the integration of Internet of Things (IoT) devices and robotics, the warehouse of the future will be smarter, more efficient, and more agile than ever before. By staying abreast of the latest developments and embracing innovation, businesses can position themselves for success in the rapidly changing landscape of warehouse management.

By incorporating warehouse optimization solutions from Greenspace Industrial into your operations, you can revolutionize your day-to-day processes and stay ahead of the competition. Contact us today to learn more about how we can help you transform your warehouse into a more efficient and productive facility.