In today’s fast-moving world of warehouse management, efficiency is key. This is where Pallet Load ASRS (Automated Storage and Retrieval Systems) comes into play. As businesses strive to optimize their operations, the demand for automated solutions like Pallet Load ASRS is on the rise.

Understanding Pallet Load ASRS

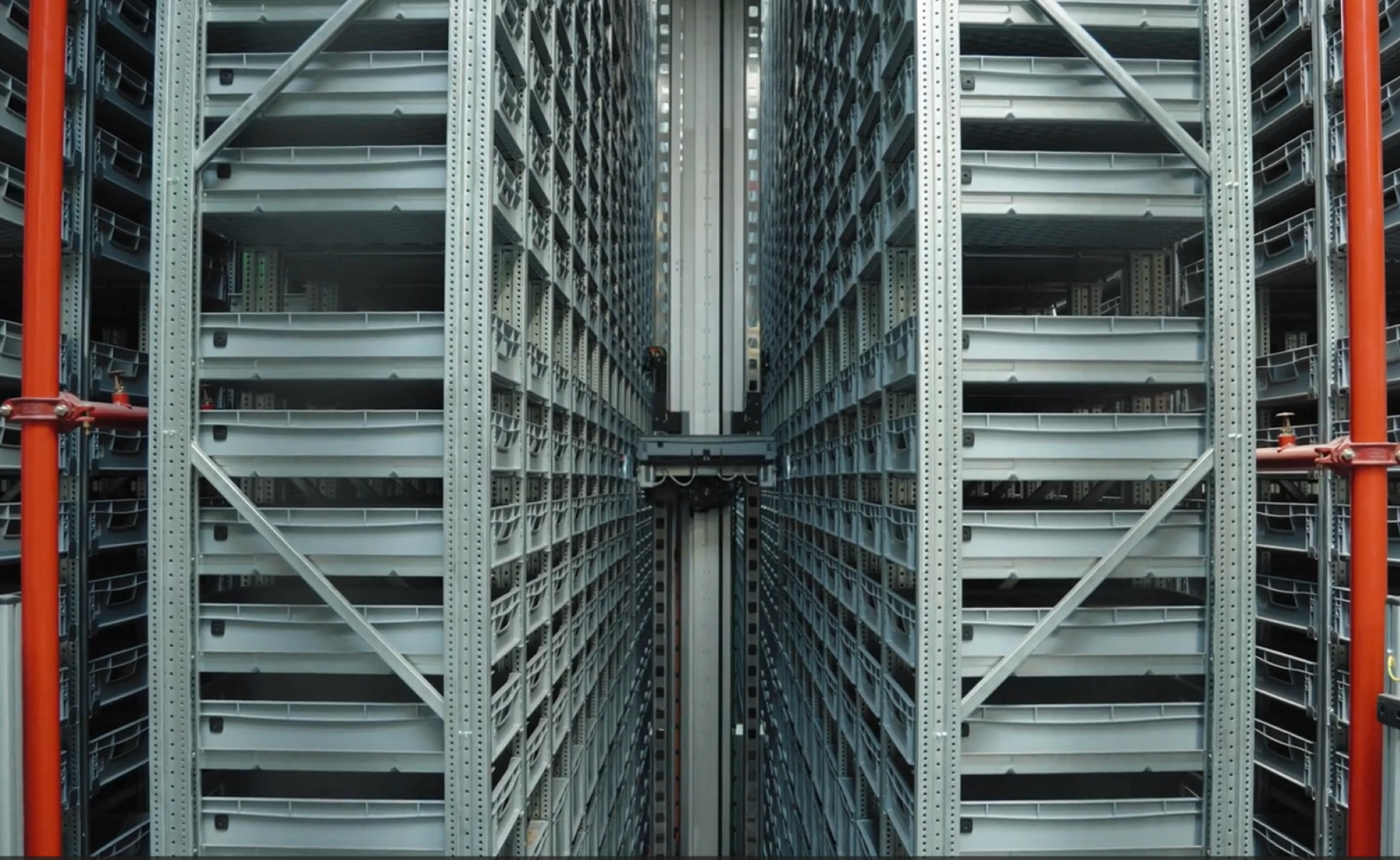

Pallet Load ASRS is a sophisticated warehouse automation technology that represents a significant advancement in the field of logistics and supply chain management. Unlike traditional storage systems, which rely heavily on manual labor for pallet handling and storage, Pallet Load ASRS utilizes state-of-the-art robotics and software solutions to automate these processes. By automating tasks such as pallet retrieval, storage, and transportation, Pallet Load ASRS not only reduces the reliance on human labor but also enhances overall operational efficiency. This automation enables warehouses to operate with greater speed and precision, leading to improved inventory management and order fulfillment capabilities.

Furthermore, Pallet Load ASRS offers unparalleled flexibility and scalability, making it suitable for a wide range of industries and applications. Whether dealing with perishable goods in the food industry or heavy machinery components in manufacturing, Pallet Load ASRS can be customized to meet the specific needs of each operation. Its modular design allows for easy integration with existing warehouse infrastructure, minimizing downtime and disruption during implementation. With Pallet Load ASRS, businesses can optimize their storage space, increase throughput, and reduce operational costs, ultimately gaining a competitive edge in today’s dynamic marketplace.

Components of Pallet Load ASRS

Pallet Load ASRS typically consists of various components, including:

- Rack Structure: Designed to support the weight of pallets and provide vertical storage.

- Shuttle Systems: Autonomous vehicles that transport pallets within the rack structure.

- Conveyor Systems: Facilitate the movement of pallets to and from the ASRS.

- Control Software: Manages inventory, directs robotic movements, and optimizes storage operations.

Working Mechanism of Pallet Load ASRS

Pallet Load ASRS operates on a simple yet efficient principle. When a pallet needs to be stored or retrieved, the shuttle system moves horizontally along the rack structure, transporting the pallet to the designated storage location or retrieval point. The shuttle system is equipped with sensors and guidance mechanisms that allow it to navigate through the aisles and accurately position the pallets. Once at the desired location, the shuttle lifts the pallet and places it onto the storage rack with precision. Similarly, when a pallet needs to be retrieved, the shuttle locates the designated pallet, lifts it from the rack, and transports it to the retrieval point for outbound processing.

The working mechanism of Pallet Load ASRS is orchestrated by sophisticated control software that coordinates the movements of the shuttle system and ensures seamless integration with other warehouse operations. This control software acts as the brain of the ASRS, receiving input from various sensors and systems to optimize storage density and retrieval efficiency. It constantly monitors inventory levels, analyzes order fulfillment requirements, and dynamically adjusts the movement of pallets within the system to meet changing demands.

Through intelligent algorithms and real-time data analysis, the control software maximizes the throughput of the ASRS while minimizing energy consumption and operational costs. Overall, the working mechanism of Pallet Load ASRS is a testament to the power of automation in revolutionizing warehouse operations, enabling businesses to achieve unprecedented levels of efficiency and productivity.

Applications of Pallet Load ASRS

Pallet Load ASRS finds application in various industries, including manufacturing, distribution, and logistics. It is ideal for businesses dealing with high volumes of palletized goods and seeking to optimize their warehouse space and operational efficiency.

Types of Storage and Retrieval Machines

Storage and Retrieval Machines, also known as SRMs, are integral components of Automated Storage and Retrieval Systems (ASRS). These machines play a crucial role in efficiently storing and retrieving inventory within warehouses. There are several types of SRMs, each designed to handle different types of goods and storage configurations:

- Unit Load ASRS:

- Description: Unit Load ASRS is specifically engineered to manage large, uniform pallet loads efficiently.

- Functionality: These systems utilize automated cranes or shuttles to transport entire pallets to and from designated storage locations within the warehouse.

- Applications: Unit Load ASRS is commonly used in industries dealing with bulk materials or standardized product packaging.

- Mini Load ASRS:

- Description: Mini Load ASRS is tailored for handling smaller items stored in totes or bins.

- Functionality: These systems employ smaller-scale robotic mechanisms or conveyors to retrieve individual totes or bins from storage locations.

- Applications: Mini Load ASRS is ideal for warehouses with high-density storage requirements, where space optimization and rapid item retrieval are paramount.

- Carousel ASRS:

- Description: Carousel ASRS incorporates rotating shelves or bins to bring items directly to the operator for picking.

- Functionality: The carousel system rotates horizontally or vertically, allowing operators to access items without having to navigate through aisles.

- Applications: Carousel ASRS is commonly utilized in order fulfillment centers and distribution warehouses, where picking efficiency and ergonomic considerations are crucial.

Each type of Storage and Retrieval Machine offers unique advantages and is tailored to meet specific warehouse requirements. By leveraging the appropriate SRM technology, businesses can enhance operational efficiency, maximize storage space utilization, and improve overall productivity within their warehouse environments.

Automated Pallet Handling Systems

In the world of warehouse automation, the integration of Pallet Load ASRS with automated pallet handling systems plays a pivotal role in enhancing efficiency and productivity. These systems seamlessly manage the movement and arrangement of pallets within the warehouse environment. Let’s delve deeper into two key components of automated pallet handling:

- Pallet Conveyors: Pallet conveyors are indispensable in the smooth flow of pallets between storage locations, production areas, and shipping docks. These automated systems efficiently transport pallets along designated pathways, optimizing the movement of goods within the warehouse. By eliminating manual handling and minimizing the risk of errors, pallet conveyors contribute significantly to operational efficiency and throughput. They are capable of handling various pallet sizes and weights, making them versatile solutions for warehouse logistics.

- Palletizers: Palletizers are sophisticated machines designed to automate the stacking or arrangement of pallets for shipping or storage purposes. These systems excel in optimizing space utilization and ensuring stability in palletized loads. By utilizing advanced robotics and intelligent programming, palletizers can efficiently stack products of varying shapes, sizes, and weights onto pallets with precision and consistency. This automation not only enhances the speed of pallet loading but also minimizes the risk of product damage and improves workplace safety.

The seamless integration of pallet conveyors and palletizers with Pallet Load ASRS forms a cohesive automated pallet handling ecosystem. Together, these systems streamline the entire warehouse operation, from storage and retrieval to transportation and stacking, ultimately maximizing efficiency and driving business success.

Automated Pallet Storage and Retrieval System

Automated pallet storage and retrieval systems are the cornerstone of modern warehouse automation. These systems utilize advanced robotics and software to efficiently manage palletized inventory, optimizing storage space and streamlining operations.

With automated pallet storage and retrieval systems, businesses can:

- Maximize Efficiency: By automating the storage and retrieval process, these systems reduce the time and labor required for handling palletized goods.

- Enhance Accuracy: Automated systems ensure precise placement and retrieval of pallets, minimizing errors and improving inventory management.

Challenges and Considerations

While Pallet Load ASRS offers numerous benefits, implementation requires careful planning and consideration. Factors such as initial investment costs, space requirements, and system integration must be evaluated to ensure a successful deployment.

Implementation Process

The implementation of Pallet Load ASRS typically involves several steps, including:

- Needs Assessment: Understanding the specific requirements and objectives of the business.

- System Design: Developing a customized solution tailored to the unique needs of the operation.

- Installation and Testing: Deploying the ASRS system and conducting thorough testing to ensure functionality and reliability.

- Training: Providing comprehensive training to warehouse staff on system operation and maintenance.

- Optimization: Continuously monitoring and optimizing system performance to maximize efficiency and productivity.

Future Trends

As technology continues to evolve, the future of Pallet Load ASRS looks promising. Advancements in robotics, artificial intelligence, and data analytics are expected to further enhance the capabilities and efficiency of these systems, driving continued adoption across industries.

In conclusion, Pallet Load ASRS represents a transformative solution for businesses looking to streamline warehouse operations and improve productivity. By leveraging automation and advanced robotics, Pallet Load ASRS offers numerous benefits, including increased efficiency, optimized space utilization, and enhanced accuracy.