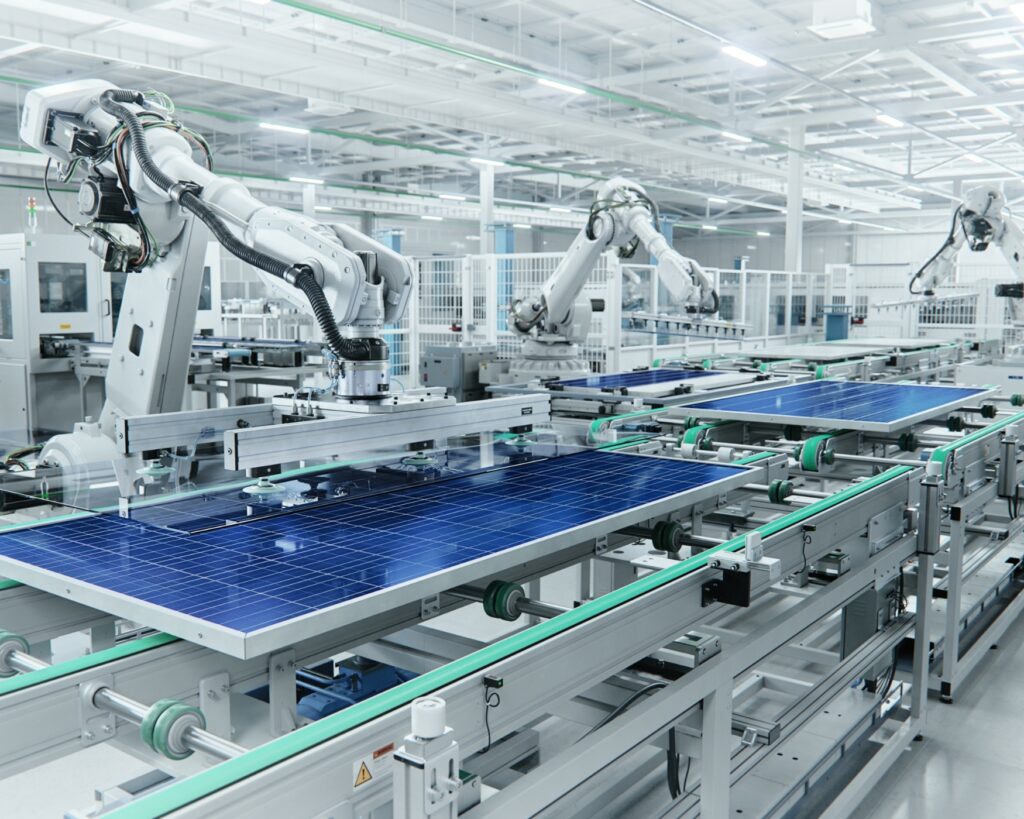

Robotic manufacturing integration refers to the seamless incorporation of robots into existing production processes, where robot integration and system integration play pivotal roles. Industrial robotics have revolutionized the manufacturing landscape by offering unparalleled precision, flexibility, and efficiency. Robot integration involves integrating these robotic systems seamlessly within a factory setting, optimizing their functionalities to align with specific production requirements. This process encompasses various stages such as planning the layout for optimal robot placement, designing custom end effectors or grippers tailored to handle specific tasks, programming the robots to perform complex maneuvers accurately and safely, and finally integrating them into existing assembly lines or workstations.

The goal of robot system integration is to enhance productivity while maintaining quality standards across all operations. By effectively merging human expertise with robotic capabilities through precise coordination between machines and workers, manufacturers can achieve enhanced throughput rates while simultaneously reducing costs associated with labor-intensive tasks.

Robotic Manufacturing Integration refers to the seamless incorporation of industrial robots into existing production systems. It involves optimizing workflows, programming, and communication to create a harmonious and efficient manufacturing environment.

Robotic Integration streamlines production by automating tasks, improving accuracy, and increasing production rates, resulting in enhanced efficiency, and reduced operational costs.

Robot Integration finds applications across various industries, including automotive, electronics, pharmaceuticals, and consumer goods, wherever precision, speed, and automation are essential.

To determine the suitability of industrial robotics for your business, you should assess your production processes, identify tasks that could be automated, evaluate the potential benefits and costs, and consult with experts in industrial automation.

Robot system Integration involves a systematic approach to incorporating robots into manufacturing processes:

The power of Robotic Manufacturing Integration lies in the utilization of advanced software components:

Robotic Integration automates tasks, reducing cycle times and increasing overall production efficiency.

Robots execute tasks with unparalleled precision, ensuring consistent product quality and reducing defects.

Automation of repetitive tasks allows human workers to focus on higher-value, strategic activities.

Integrated robotic systems can be easily adapted to accommodate changing production needs and increasing demands.

As a leader in industrial robotics solutions, we are dedicated to providing cutting-edge Robotic Manufacturing Integration services that optimize your manufacturing operations for maximum efficiency and productivity. In conclusion, Robot system Integration represents a leap forward in industrial automation, combining the power of robotics with advanced software to enhance production processes. The ability to seamlessly integrate robots into existing systems, coupled with the numerous advantages it offers, makes it an invaluable tool for modern manufacturing. To harness the potential of Robotic Manufacturing Integration and elevate your production capabilities, reach out to us today.

Stay Updated on Innovations & Industry Trends

Your privacy is guaranteed. Your information will not be shared with 3rd party data collections. By submitting this form, you consent to receive electronic communications from Greenspace Industrial.