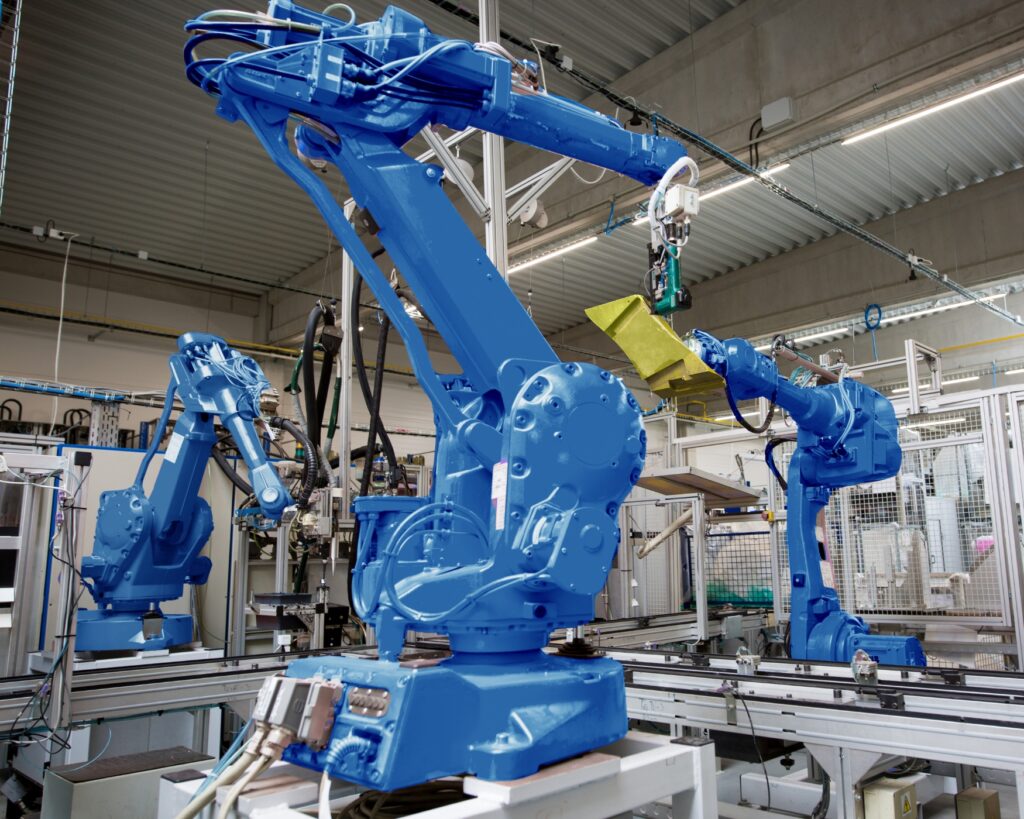

Pick and Place Robotics is a cutting-edge technological innovation that has revolutionized the industrial automation landscape. With its exceptional precision, speed, and efficiency, Pick and Place Automation systems have become an indispensable tool for industries around the world. These robotic arms are designed to automate repetitive tasks involved in material handling, assembly lines, packaging processes, and more. By seamlessly integrating advanced sensors and intelligent algorithms into their programming, these robots can accurately identify objects of varying shapes and sizes within milliseconds.

The Industrial Automation Company utilizes state-of-the-art engineering techniques to ensure seamless integration of Pick and Place Robotic Arms into existing production lines or designing customized solutions tailored to specific requirements. This technology not only enhances productivity but also significantly reduces human errors while ensuring worker safety by taking over physically demanding tasks. Whether operating in automotive manufacturing plants or e-commerce warehouses, Pick and Place Robotic Arms have proven themselves as reliable workhorses capable of delivering consistent performance with utmost precision day after day.

Pick & Place Robotic Arms are specialized robotic systems designed to precisely pick up objects from one location and accurately place them in another. These robotic arms are equipped with advanced sensors, grippers, and motion control mechanisms to perform these tasks with high precision.

By automating the pick and place process, these robotic arms significantly enhance efficiency by reducing human intervention, minimizing errors, and increasing throughput.

Pick and place robotics and Pick and Place Automation systems find applications in industries such as electronics assembly, automotive manufacturing, food and beverage packaging, pharmaceuticals, logistics, and more.

The ROI from pick and place robotics can be substantial, encompassing factors like increased productivity, minimized errors, reduced labor costs, improved quality, and shorter production cycles, all contributing to enhanced overall efficiency and profitability.

Pick & Place Robotic Arms operate through a series of coordinated actions, allowing them to handle objects with utmost accuracy:

The prowess of Pick & Place Robotic Arms is driven by powerful software components:

Pick & Place Robotic Arms execute tasks with unparalleled precision, reducing errors and ensuring consistent product quality.

These robotic arms work tirelessly, 24/7, leading to improved production rates and reduced operational costs.

Pick & Place Robotic Arms can be programmed to handle a wide range of objects, making them versatile for various applications.

By automating repetitive and labor-intensive tasks, AMRs contribute to reduced labor costs and increased overall productivity

As a leading Industrial Automation Company, we are committed to providing cutting-edge Pick and Place Robotics solutions that optimize your operations for efficiency, precision, and cost-effectiveness. In conclusion, Pick & Place Robotic Arms are at the forefront of industrial automation, redefining the way objects are handled and manipulated. Their ability to perform precise pick and place tasks, coupled with advanced software intelligence, offers a multitude of advantages across industries. To embrace the power of Pick and Place Automation and elevate your manufacturing processes, get in touch with us today.

Stay Updated on Innovations & Industry Trends

Your privacy is guaranteed. Your information will not be shared with 3rd party data collections. By submitting this form, you consent to receive electronic communications from Greenspace Industrial.