Packaging Equipment is the backbone to any logistics business, as they ensure that products are transported safely and efficiently from one location to another. With the right packaging equipment in place, businesses can improve their operational efficiency while also reducing costs associated with damaged or lost shipments. The right kind of equipment helps businesses stay ahead of their competitors while ensuring that their customers receive high-quality products every time.

Your privacy is guaranteed. Your information will not be shared with 3rd party data collections. By submitting this form, you consent to receive electronic communications from Greenspace Industrial.

Stretch wrappers are an essential tool for any warehouse or distribution center that needs to package and protect their products efficiently. These machines use a roll of stretch film to tightly wrap pallets, boxes, or other large items for transport or storage. Modern stretch wrappers come equipped with advanced technology that ensures consistent wrapping quality without any operator intervention.

With such benefits, it’s no wonder why stretch wrappers are becoming increasingly popular in industries ranging from food processing to automotive manufacturing. With a stretch wrapper on hand, businesses can save time, reduce waste from overwrapped products, and ensure that their goods arrive at their destination intact and undamaged.

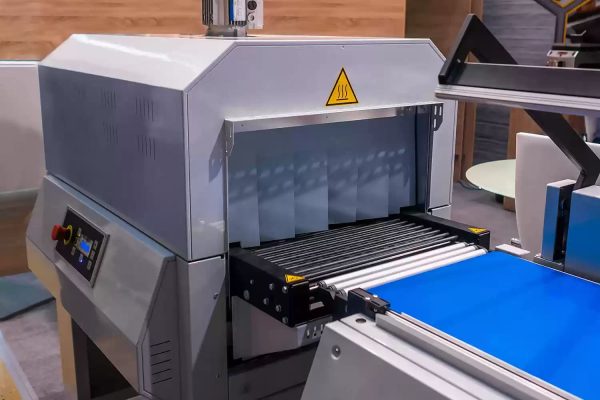

Shrink wrapping machine is a highly efficient and effective tool used to package products in a protective film. The device works by wrapping the product in plastic film, which is then shrunk tightly around it using heat. This process not only keeps the product clean and safe from damage, but also enhances its appearance by giving it a polished finish.

Shrink wrap packaging is particularly useful for items that are irregularly shaped or have sharp edges as it conforms closely to their contours without tearing or puncturing. Moreover, this packaging method reduces waste and increases the shelf life of products as they are shielded against moisture, dirt, dust, and other environmental factors that could cause deterioration over time. With its ability to quickly seal packages in bulk with precision accuracy, the shrink-wrapping machine has become an indispensable asset in various industries including food manufacturing, pharmaceuticals production and e-commerce shipping among others.

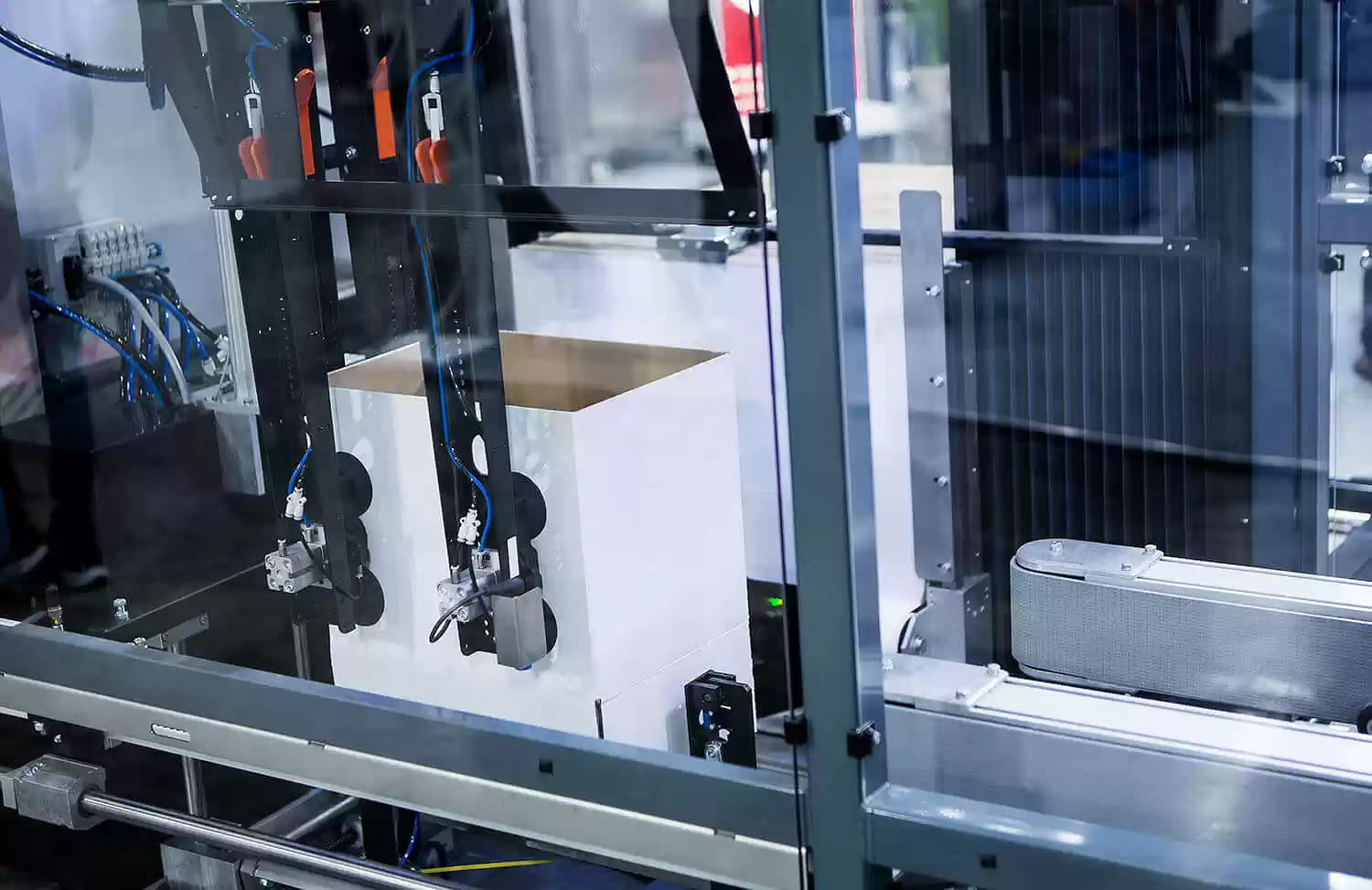

Case erectors are a crucial piece of equipment in the packaging industry that help streamline the process of preparing and assembling cardboard boxes. These machines are designed to do just what their name suggests: erect or set up corrugated cases for packaging products. These machines can handle various types of box styles, shapes, and sizes with ease. One of the significant advantages of using a case erector is that it reduces labor costs as it can do the job much faster than manually forming boxes.

Additionally, by eliminating human error in manual box assembly, it creates consistent quality control standards that ensure all products fit perfectly into their respective containers during shipment or storage. Another great feature is that they are fully customizable to meet specific production needs depending on the industry’s type or size requirements – speedy performance being an example of this customization.

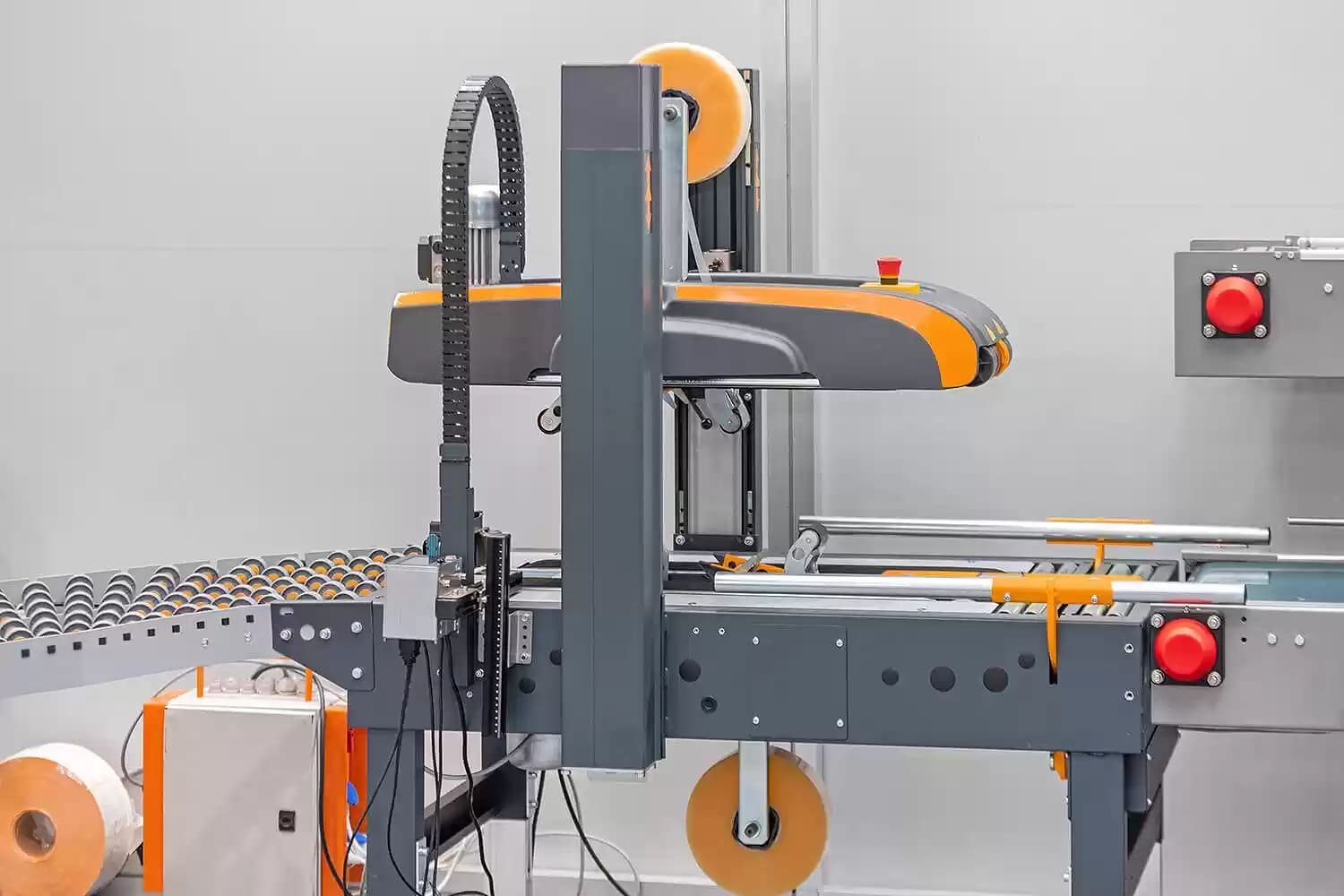

Case sealers are essential machines that establish the safety and protection of products during transportation. The case sealer applies pressure to the flaps of the box, ensuring they stick together as intended. With advancements in technology, modern case sealers can handle a variety of boxes with different sizes and shapes, making them highly versatile for any industry that requires packaging solutions.

Additionally, many case sealers come equipped with sensors that detect if there’s anything wrong with the sealing process or if there’s an obstruction on the conveyor belt; this ensures maximum efficiency and productivity while minimizing errors and downtime. Overall, investing in a high-quality case sealer can save businesses time, money, and headaches while ensuring their products arrive at their intended destinations safely and securely.

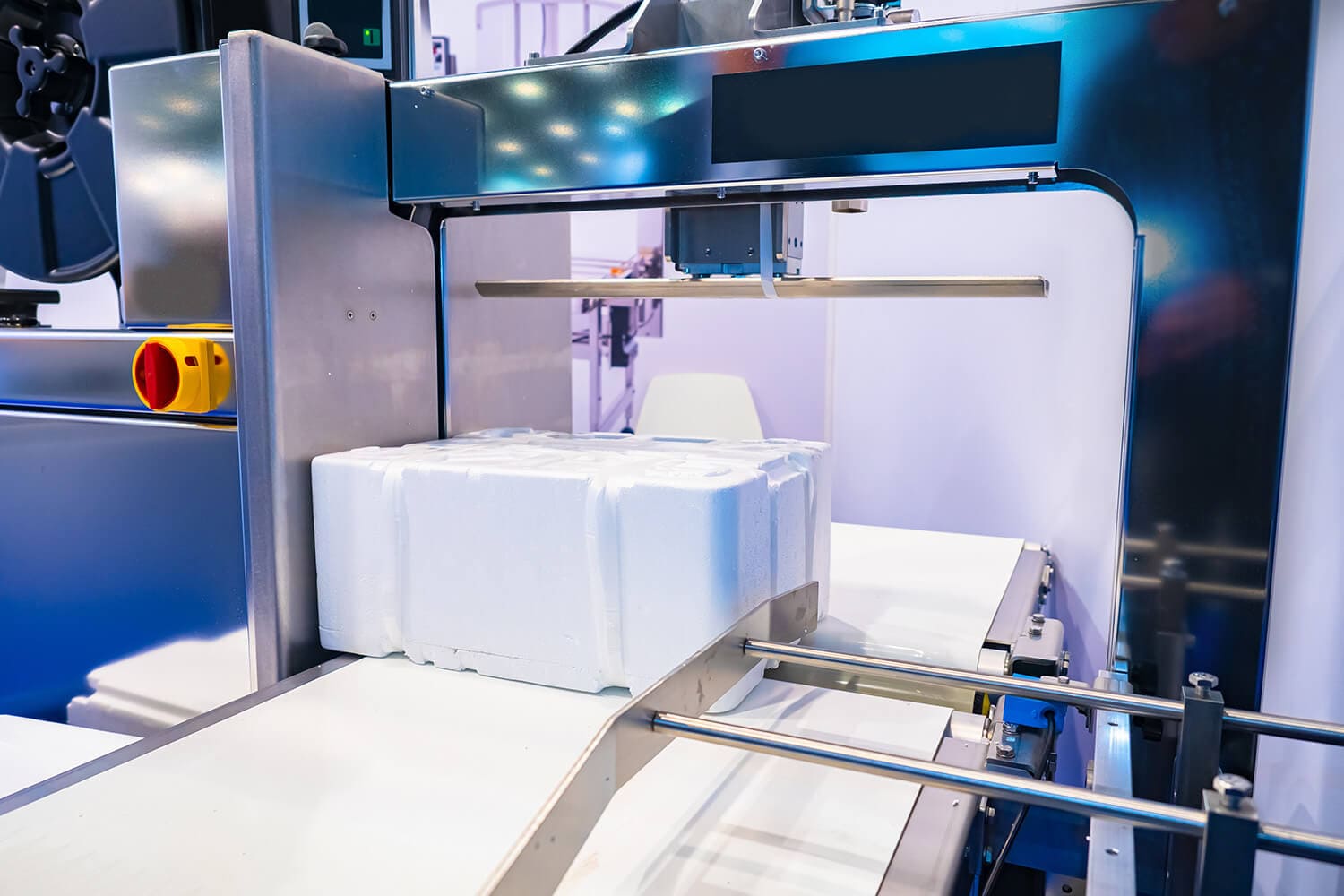

Sleeving and cartoning are two essential processes in the packaging industry that ensure products reach their destination safely and securely. Both these methods are efficient ways of packing a large number of items to be shipped or stored. Sleeving involves placing a product into a sleeve made from paperboard, plastic film, or other materials, which not only protects it but also provides additional branding opportunities for the company.

On the other hand, cartoning refers to placing products into pre-made boxes that come in different sizes and shapes. This process is particularly useful when dealing with various products or quantities that require different types of packaging solutions. Automated cartoners have a range of capabilities including filling multiple product variations into one box seamlessly at high speeds. This ensures efficient delivery times to retailers’ shelves worldwide with minimal human errors that may occur during manual handling operations.

Regardless of whether you choose sleeving or cartoning, both options offer excellent protection against damage during shipping while guaranteeing your product looks professional and attractive on store shelves.

Strapping machines are a fundamental tool for businesses looking to optimize their packaging and shipping processes. These machines use strong, durable straps made of materials like polyester, polypropylene or steel to securely hold items together during transit. The benefits of a strapping machine extend beyond just improved security- they also save time in the packing process.

With an automatic strapping machine, items can be quickly strapped without requiring manual labor, allowing employees to focus on other important aspects of their job. Additionally, many models offer adjustable tension controls and can handle different strap sizes and strengths depending on the needs of the business. By investing in a high-quality strapping machine, companies can ensure that their products arrive at their destination safely and efficiently while streamlining their operations in the process.

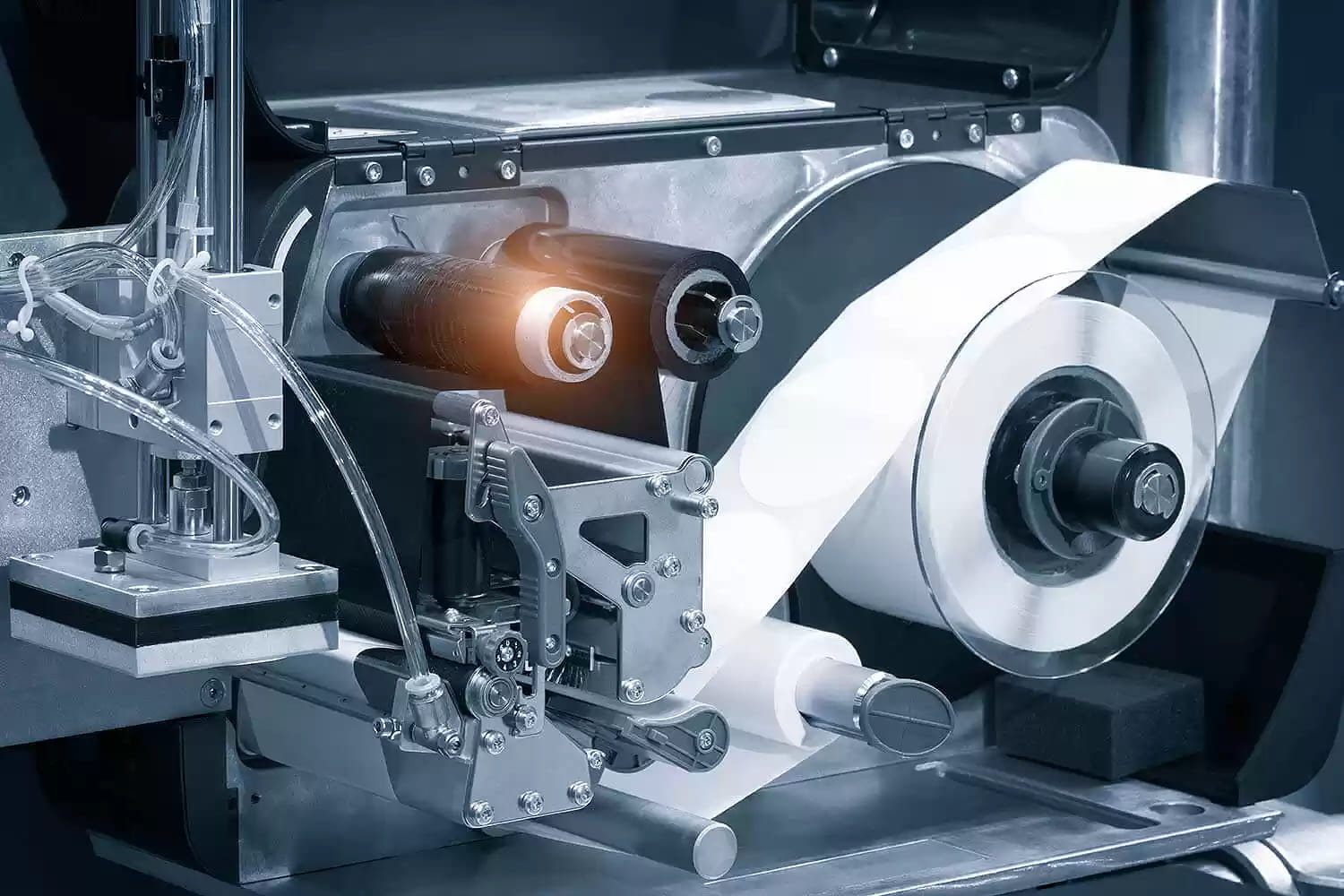

Labelling machines are innovative devices that have made a significant impact in various industries. These machines come in different types and sizes designed to meet specific labelling needs, such as product identification, branding, batch numbering or expiry dates. One of the primary benefits of labelling machines is their time-saving ability. They can work rapidly and accurately by applying labels on products without any errors compared to manual labeling methods which require much more time and effort owing to their tediousness.

Additionally, they offer versatility by providing options for users to customize their label designs using pre-installed software applications. These machines can handle large batches effortlessly while significantly reducing labour costs and increasing production efficiency. Its advanced sensors ensure precise positioning adhesives wherever it’s needed whether applying paper or plastic labels on curved or flat parcels in varying sizes.

Robotic palletizers are advanced and efficient machines designed to automate the process of palletizing products in industries. These innovative devices use robotic arms that can move, stack and load products onto pallets with great precision and speed. They come equipped with an extensive range of sensors that ensure accuracy in stacking patterns, making them ideal for companies looking for high levels of consistency.

Their versatility allows them to handle different sizes and shapes of products while optimizing space by reducing wastage, thus saving time and costs for businesses. Moreover, these devices significantly reduce injury risks posed by traditional manual methods of handling heavy objects – thus ensuring worker safety. By utilizing cutting-edge technology such as machine learning algorithms, Robotic Palletizers calculate the most efficient way of loading goods without wasting valuable space or placing undue strain on products during transportation.

Stay Updated on Innovations & Industry Trends

Your privacy is guaranteed. Your information will not be shared with 3rd party data collections. By submitting this form, you consent to receive electronic communications from Greenspace Industrial.