In a logistics landscape driven by speed, precision, and scalability, Daniella has taken a significant leap forward. A major electrical goods distributor in Hungary, Daniella recently implemented a state-of-the-art Mini Load Automated Storage and Retrieval System (ASRS) paired with a robust conveyor infrastructure and intelligent software. This installation marks a shift toward smarter, more efficient material handling in mid-sized distribution centers.

A Vision in Motion: Understanding the ASRS Rendering

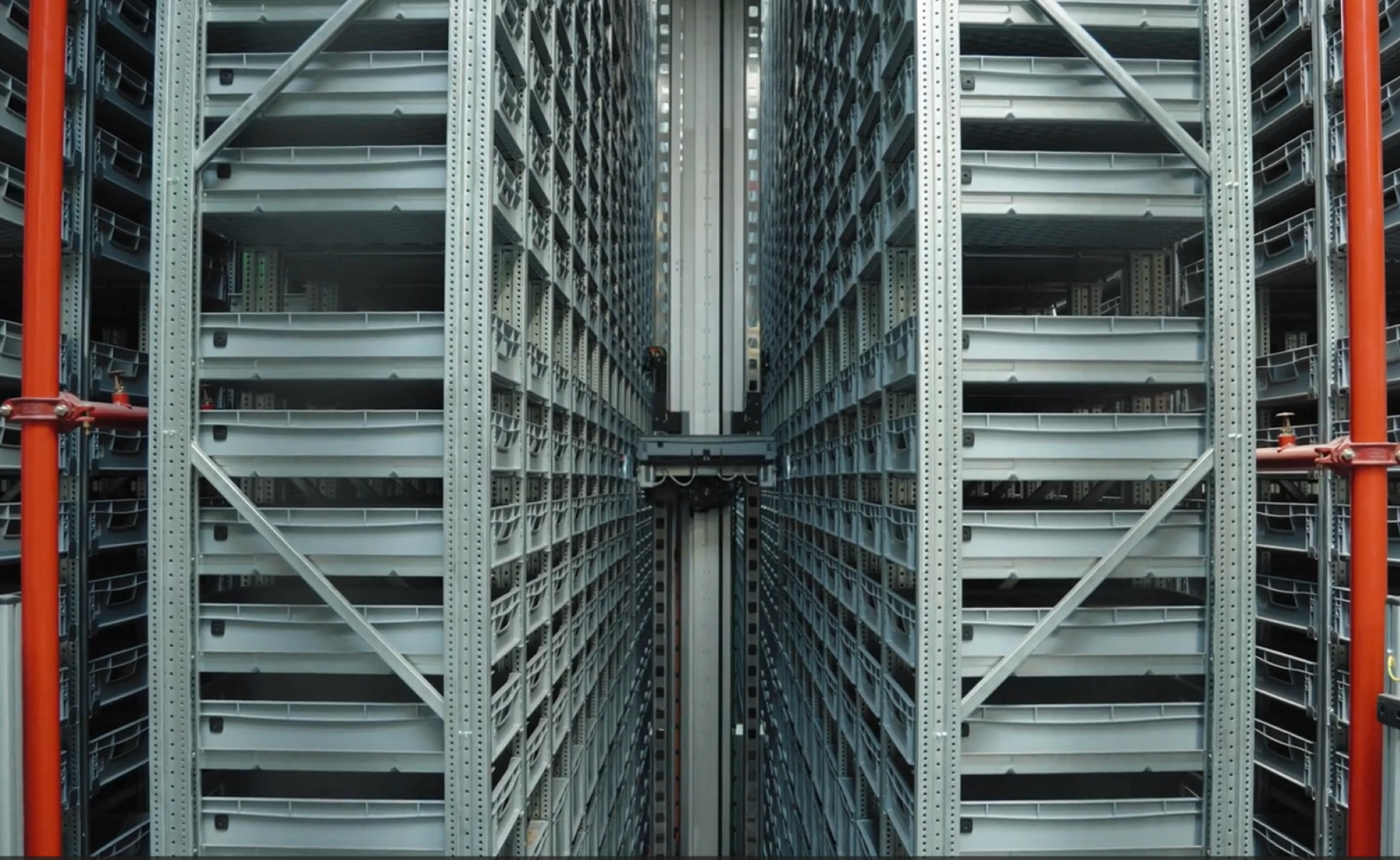

The video opens with a striking 3D rendering that previews the system before it was built. This digital model provides a top-to-bottom view of the automated warehouse, clearly illustrating:

- Tall, high-density vertical storage aisles optimized for small-part inventory

- Agile shuttle systems navigating rails to retrieve and store totes

- A network of automated conveyors transferring totes to pick stations

- Ergonomic operator workstations, seamlessly integrated with software for guided picking

The rendering is a clear blueprint of how technology, movement, and human interaction come together in a unified material handling ecosystem.

What Was Installed at Daniella

The full system was brought to life with precision-engineered components, including:

Mini Load ASRS Units

Designed to store small parts and lightweight totes in a dense, multi-level format, accessed by shuttles with high-speed performance.

Integrated Conveyor Lines

Strategically laid out to connect ASRS towers with workstations, enabling a nonstop flow of inventory and order fulfillment.

Smart Picking Stations

Operator-friendly zones equipped with visual cues, ergonomic design, and real-time system prompts for fast, accurate picking.

Warehouse Management Software (WMS)

The brain behind the operation-managing inventory locations, shuttle movements, conveyor routing, and order processing with precision.

The Results: Why It Matters

- Up to 80% Space Optimization

With vertical automation, Daniella maximized storage capacity without expanding its footprint—crucial in high-density operations. - Streamlined Order Fulfillment

Automated tote retrieval and conveyor transport cut manual handling time, accelerating the overall pick-and-pack cycle. - Improved Accuracy and Traceability

Digital tracking of every tote, combined with software-directed workflows, reduced picking errors and improved visibility. - Reduced Physical Labor

Repetitive tasks like walking, searching, and lifting are now automated, allowing staff to focus on value-added tasks in safer conditions. - Scalable Infrastructure

As product lines and order volumes grow, Daniella can expand the system modularly—without disrupting the existing layout.

A Future-Ready Warehouse

Daniella’s investment in warehouse automation is a clear response to rising order complexity, customer expectations, and operational pressure. The project demonstrates how Mini Load ASRS technology, when paired with the right conveyor logic and user-centered design, can dramatically enhance warehouse performance.

The transition from a 3D rendering to a fully operational system captures the essence of innovation in warehousing: building smarter, faster, and more scalable supply chains.

Curious how automated storage and conveyor solutions can elevate your operations?

Let’s talk about a solution tailored to your needs.