Automated Storage and Retrieval Systems

Automated Storage and Retrieval Systems AS/RS Technologies

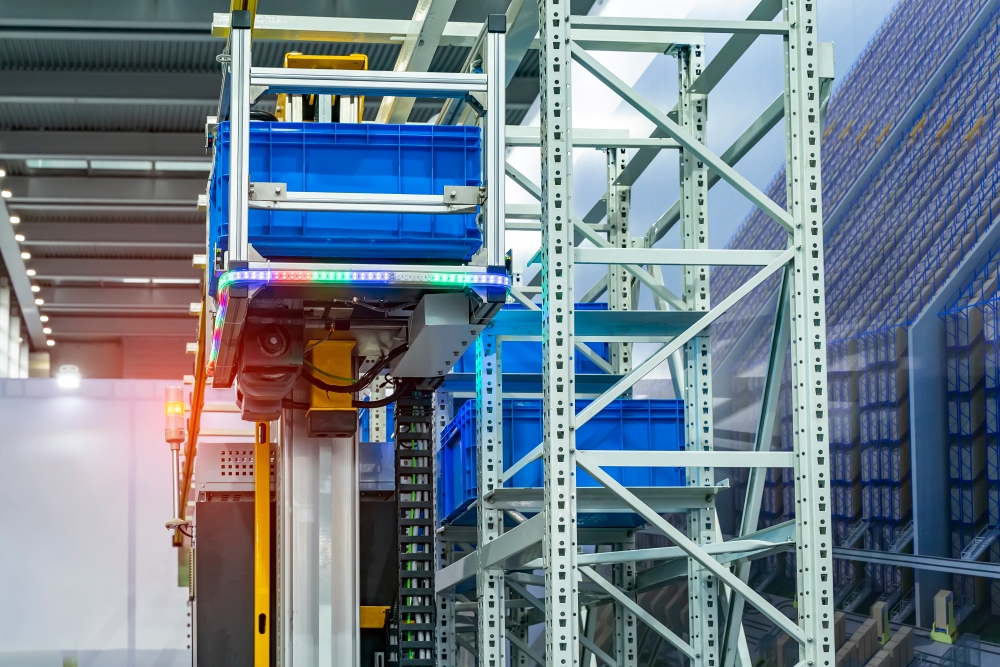

At Greenspace Industrial, we are at the forefront of revolutionizing the warehousing industry through our state-of-the-art Automated Storage and Retrieval Systems (AS/RS) and Vertical Lift Module (VLM). As a leading Warehouse Automation Company in Canada, we pride ourselves on offering cutting-edge technologies that optimize efficiency, streamline operations, and boost productivity for businesses across Canada.

Definition and Overview

Automated pallet storage and retrieval system (AS/RS) are advanced solutions designed to automate the storage and retrieval of goods in a warehouse or distribution center. These systems use computerized controls and automated equipment to efficiently store items in designated locations and retrieve them as needed. AS/RS can handle a wide range of items, from small parts to large pallets, making them versatile solutions for various industries.

Importance of AS/RS in Modern Warehousing

In today’s fast-paced business environment, the demand for efficient, accurate, and speedy warehouse operations is higher than ever. AS/RS plays a crucial role in modern warehousing by enhancing productivity, reducing errors, and optimizing space utilization. They allow businesses to meet customer demands more effectively, improve order accuracy, and maintain a competitive edge in the market.

Types Of Automated Storage and Retrieval System

Pallet-Load AS/RS

Pallet-Load ASRS or Unit-Load AS/RS are designed to handle large, heavy loads such as pallets. These systems use cranes or shuttles to move items to and from storage locations, making them ideal for industries with high-volume storage needs. The cranes or shuttles are capable of lifting and transporting heavy weights with precision, ensuring that items are stored and retrieved efficiently without damage. In addition to their high-load capacity, Pallet-Load AS/RS systems offer significant advantages in terms of inventory control and space utilization. By automating the storage and retrieval processes, these systems reduce the need for manual handling, thereby minimizing the risk of errors and accidents. This makes them particularly beneficial for sectors such as manufacturing, distribution, and automotive, where large quantities of goods need to be managed systematically.Mini-load AS/RS

Mini-Load AS/RS are designed for smaller items, typically stored in totes or trays. These systems use smaller cranes or shuttles to retrieve items, making them suitable for industries with high SKU counts and smaller item sizes. The mini-load systems are adept at handling lightweight and medium-sized products, ensuring quick and accurate picking processes.

The compact design of Mini-Load AS/RS systems allows for efficient use of space within a warehouse. By storing items in high-density racks and utilizing vertical space, businesses can maximize their storage capacity without expanding their physical footprint. This makes Mini-Load AS/RS an excellent choice for e-commerce, pharmaceuticals, and electronics industries, where a large variety of small items need to be managed efficiently.

Shuttle Systems

Shuttle systems offer rapid and accurate item retrieval, significantly improving order fulfillment times. They can be integrated with other automation technologies, such as conveyors and robotic picking arms, to create a seamless and efficient warehouse operation. Industries such as retail, food and beverage, and distribution centers benefit from the scalability and adaptability of shuttle systems, allowing them to respond quickly to changing demands.

Vertical Lift Modules (VLMs)

Vertical Lift Modules (VLMs) are enclosed systems that store items on trays and deliver them to an operator with the push of a button. VLMs optimize vertical space utilization and improve picking accuracy and speed. By storing items in a compact and organized manner, VLMs can significantly reduce the amount of floor space required for storage.

In addition to space savings, VLMs enhance worker productivity and ergonomics. Items are delivered at an optimal working height, reducing the need for bending, stretching, or climbing. This not only speeds up the picking process but also minimizes the risk of workplace injuries. VLMs are particularly effective in environments where high-value or sensitive items need to be stored securely, such as in the aerospace, healthcare, and electronics industries.

Horizontal Carousels

Horizontal carousels consist of a series of bins or shelves that rotate horizontally to deliver items to an operator. These systems are ideal for high-density storage and fast retrieval of small items. By bringing the stored items directly to the operator, horizontal carousels eliminate the need for employees to walk around the warehouse, thereby reducing retrieval times and increasing productivity.

Horizontal carousels are highly efficient for order picking and fulfillment processes, especially in environments with a high volume of small, fast-moving items. They can be integrated with pick-to-light systems to further enhance accuracy and speed. Industries such as retail, pharmaceuticals, and spare parts distribution can greatly benefit from the space-saving and efficiency-boosting capabilities of horizontal carousels.

Vertical Carousels

Vertical carousels operate similarly to horizontal carousels but rotate vertically. They are used for storing and retrieving small to medium-sized items and optimizing vertical space in a warehouse. By utilizing vertical space, these systems can significantly increase storage capacity without expanding the warehouse footprint.

The design of vertical carousels ensures that items are stored in a secure and organized manner, making it easy to manage inventory and track items. Operators can access items quickly and ergonomically, improving overall efficiency. Vertical carousels are particularly useful in industries where space is at a premium, such as healthcare, electronics, and automotive parts storage, providing a compact and efficient storage solution.

Automated Storage Companies Benefits

Increased Storage Capacity

AS/RS maximizes storage density by utilizing vertical space and compact storage layouts. This allows businesses to store more items in the same footprint, increasing overall storage capacity.

Improved Inventory Accuracy

Automated systems reduce human error in inventory management. AS/RS provides precise tracking and control of inventory, leading to improved accuracy and reduced discrepancies.

Enhanced Operational Efficiency

AS/RS streamlines warehouse operations by automating repetitive tasks such as picking, packing, and storing items. This leads to faster order processing and increased throughput.

Reduced Labor Costs

By automating labor-intensive tasks, AS/RS reduces the need for manual labor. This leads to significant cost savings in labor expenses and reduces the risk of workplace injuries.

Better Space Utilization

ASRS optimizes the use of available space by utilizing vertical storage and compact layouts. This allows businesses to make the most of their warehouse space and avoid the need for costly expansions.

ASRS Technologies and Innovations

Robotics and Automation

Robotic technology is a key component of ASRS. Robots are used for tasks such as picking, packing, and transporting items, enhancing efficiency and accuracy.

IoT and Smart Warehousing

The Internet of Things (IoT) enables real-time monitoring and control of warehouse operations. Smart warehousing solutions use IoT to optimize inventory management and improve overall efficiency.

AI and Machine Learning in ASRS

Artificial intelligence (AI) and machine learning are being integrated into ASRS to enhance their capabilities. These technologies enable systems to learn and adapt, improving efficiency and accuracy over time.

Energy Efficiency and Sustainability

Modern ASRS are designed with energy efficiency in mind. They use energy-saving technologies and sustainable practices to reduce their environmental impact.

Applications of AS/RS in Different Industries

Manufacturing

In manufacturing, AS/RS is used to store raw materials, components, and finished products. They improve inventory control, reduce production downtime, and enhance overall efficiency.

Distribution Centers

Distribution centers use AS/RS to handle high volumes of orders quickly and accurately. These systems improve order fulfillment rates and reduce shipping errors.

Retail

Retail businesses use AS/RS to manage inventory in warehouses and distribution centers. AS/RS helps retailers maintain accurate stock levels, reduce shrinkage, and improve customer satisfaction.

Pharmaceuticals

The pharmaceutical industry benefits from AS/RS by ensuring the accurate storage and retrieval of sensitive products. AS/RS provides precise control over inventory and helps maintain regulatory compliance.

Food and Beverage

AS/RS is used in the food and beverage industry to store perishable items and ensure proper rotation of stock. These systems improve inventory management and reduce waste.

Automotive

In the automotive industry, AS/RS is used to store and retrieve parts and components. They improve inventory accuracy, reduce downtime, and enhance production efficiency.

Future Trends in AS/RS

Emerging Technologies

New technologies are continually being developed to enhance the capabilities of AS/RS. Staying informed about these emerging technologies helps businesses stay ahead of the competition.

Market Trends and Predictions

Understanding market trends and predictions for AS/RS helps businesses make informed decisions about automation investments and future-proof their operations.

Innovations Driving the Future of Warehousing

Innovations in automation, robotics, AI, and IoT are driving the future of warehousing. These advancements are expected to further improve efficiency, accuracy, and sustainability.

Greenspace Industries AS/RS Solutions

Overview of Our AS/RS Offerings

Greenspace Industrial offers a comprehensive range of AS/RS solutions tailored to meet the unique needs of businesses across various industries. Our solutions are designed to enhance efficiency and productivity.

Customization and Flexibility

We provide customized ASRS solutions that are flexible and scalable to meet the changing needs of businesses. Our systems can be tailored to specific storage and retrieval requirements.

Implementation Process

Our implementation process ensures a seamless transition to automated store and retrieval systems. We provide comprehensive support from initial consultation to installation and ongoing maintenance.

Customer Support and Service

We offer reliable customer support and service to ensure the smooth operation of our AS/RS solutions. Our team is available to assist with any issues and provide ongoing maintenance and support.

Frequently Asked Questions

An AS/RS is a computerized system that automates the storage and retrieval of goods in a warehouse. It uses automated equipment to store items in designated locations and retrieve them as needed.

ASRS improves inventory accuracy by reducing human error and providing precise tracking and control of inventory. This leads to more accurate stock levels and fewer discrepancies.

The cost of implementing ASRS includes the initial investment, ongoing maintenance costs, and potential ROI. Businesses need to evaluate these factors to determine the financial benefits of automation.

Modern ASRS are designed with energy efficiency in mind and use sustainable practices to reduce their environmental impact. This includes energy-saving technologies and eco-friendly materials.

ASRS is used in various industries, including manufacturing, distribution centers, retail, pharmaceuticals, food and beverage, and automotive. They enhance efficiency and productivity in these sectors.

Conclusion

Automated Storage and Retrieval System (AS/RS) are revolutionizing the warehousing industry by enhancing efficiency, accuracy, and productivity. At Greenspace Industrial, we offer state-of-the-art AS/RS solutions that meet the diverse needs of businesses across Canada. By implementing ASRS, businesses can optimize their operations, reduce costs, and maintain a competitive edge in the market. Contact us today to learn more about how our ASRS solutions can benefit your business.

Greenspace News

Stay Updated on Innovations & Industry Trends

Contact us to learn more about our

products and services.

Your privacy is guaranteed. Your information will not be shared with 3rd party data collections. By submitting this form, you consent to receive electronic communications from Greenspace Industrial.