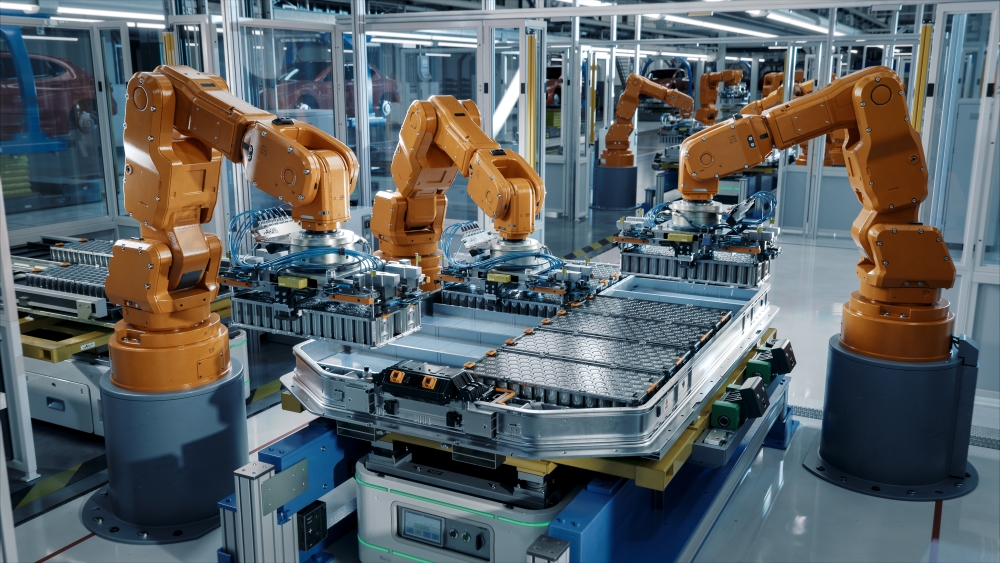

At Greenspace Industrial, we are dedicated to empowering businesses to streamline their operations with our cutting-edge solutions. One of the most transformative advancements we leverage is Robotic Process Automation (RPA). RPA is revolutionizing workflows, particularly in warehouses, making them faster, more efficient, and error-free. Let’s dive into how Robotic Process Automation in warehouses is streamlining operations and redefining logistics management.

What Is Robotic Process Automation (RPA)?

Understanding the Basics

RPA involves deploying software robots to handle repetitive and rule-based tasks traditionally performed by humans. These bots mimic human actions, executing tasks like data entry, inventory tracking, and order processing with unparalleled speed and accuracy.

The Relevance of RPA in Warehousing

Warehouses are a hub of complex activities that require precision, speed, and coordination. From inventory control to shipment management, the potential for automation is vast. Robotic Process Automation in warehouses addresses these challenges, creating a smoother and more efficient operational flow.

The Impact of RPA on Warehouse Operations

1. Transforming Inventory Management

Inventory management is a cornerstone of warehouse operations. RPA ensures real-time updates by automating stock tracking and auditing processes. These bots integrate seamlessly with warehouse management systems (WMS), providing accurate data and reducing discrepancies.

2. Enhancing Order Fulfillment

Order fulfillment involves multiple steps, including picking, packing, and shipping. With RPA, warehouses can automate the processing of orders, ensuring faster turnaround times while maintaining high accuracy.

3. Simplifying Returns Management

Handling returns can be resource-intensive and error-prone. RPA streamlines this process by automating data entry, updating inventory levels, and processing refund requests efficiently.

4. Optimizing Resource Allocation

By analyzing operational data, RPA helps allocate resources, both human and material, more effectively. This ensures optimal productivity across various warehouse functions.

Key Advantages of Robotic Process Automation in Warehouses

1. Error Reduction

Manual tasks often lead to errors that can disrupt operations. RPA eliminates these mistakes by ensuring consistent accuracy across all tasks.

2. Time Efficiency

Repetitive processes that take hours manually can be completed in seconds with RPA, significantly speeding up workflows.

3. Cost Effectiveness

Automating tasks reduces the need for extensive manual labor, cutting operational costs and boosting the bottom line.

4. Improved Scalability

As warehouse demands fluctuate, RPA systems can scale up or down effortlessly, adapting to the workload without requiring additional resources.

5. Enhanced Decision-Making

With real-time data analytics powered by RPA, managers can make informed decisions to improve operational efficiency further.

Real-World Applications of RPA in Warehousing

1. Automated Data Capture

RPA bots can read and process data from invoices, delivery notes, and inventory lists, eliminating the need for manual data entry.

2. Warehouse Layout Optimization

RPA-driven analytics identify patterns in product movement, helping design layouts that minimize travel time and increase efficiency.

3. Demand Forecasting

By analyzing historical data and current trends, RPA tools predict inventory requirements, ensuring adequate stock levels at all times.

4. Workflow Automation

Processes like generating shipping labels, sending notifications, and tracking deliveries can be entirely automated using RPA, ensuring smooth communication across supply chain stakeholders.

How Greenspace Industrial Implements RPA in Warehouses

Tailored Solutions for Every Client

We know that no two warehouses operate the same way. That’s why we customize Robotic Process Automation in warehouses to address the specific needs of your business. Whether it’s inventory management, order processing, or shipment tracking, our solutions are designed to deliver maximum impact.

Integration Made Easy

At Greenspace Industrial, we simplify the RPA integration process. Our experts work closely with your team to ensure minimal disruptions during implementation, keeping your operations on track.

Ongoing Support and Upgrades

The world of automation evolves rapidly. To keep you ahead, we provide ongoing support and regular updates, ensuring your warehouse remains competitive and efficient.

Challenges in Adopting Robotic Process Automation in Warehouses

1. Initial Costs

The upfront investment for RPA technology can appear daunting. However, the long-term savings and efficiency gains far outweigh the initial expense.

2. Technological Adaptation

Integrating RPA with existing warehouse systems might seem challenging, but with the right expertise, it becomes a seamless transition.

3. Workforce Concerns

Automation can sometimes lead to apprehension among employees. By highlighting how RPA complements rather than replaces human roles, businesses can foster acceptance and collaboration.

The Future of Robotic Process Automation in Warehouses

1. AI-Powered Automation

The combination of artificial intelligence (AI) and RPA is set to make automation even smarter. AI can enable RPA systems to learn and adapt, allowing them to handle more complex warehouse tasks.

2. Sustainable Warehousing

RPA contributes to sustainability by optimizing processes, reducing waste, and minimizing energy consumption.

3. Greater Integration with IoT

The Internet of Things (IoT) and RPA will work together to create hyper-connected warehouses, where every device communicates seamlessly to improve efficiency and accuracy.

Why Choose Greenspace Industrial for Your RPA Needs?

Expertise You Can Trust

With years of experience, Greenspace Industrial is a pioneer in implementing cutting-edge solutions like Robotic Process Automation in warehouses.

Customer-Centric Approach

Your success is our priority. We work alongside you to develop automation strategies that align with your goals and operational requirements.

Proven Track Record

Our portfolio speaks volumes. Clients who have adopted our RPA solutions have experienced remarkable improvements in efficiency, accuracy, and cost savings.

Commitment to Innovation

We’re not just about adopting technology; we’re about driving innovation. Our team continuously explores advancements to keep your warehouse operations at the forefront of the industry.

Conclusion

Robotic Process Automation in warehouses is no longer a luxury; it’s a necessity for businesses aiming to stay competitive in today’s dynamic market. By automating repetitive tasks, improving accuracy, and streamlining operations, RPA is transforming warehouse management.

At Greenspace Industrial, we’re proud to be at the forefront of this transformation. Our tailored RPA solutions are designed to meet the unique needs of your warehouse, ensuring a seamless integration that maximizes efficiency and minimizes disruptions. Whether it’s inventory management, order fulfillment, or resource allocation, our expertise ensures your warehouse operates at its peak potential.

With Robotic Process Automation in warehouses, the future of logistics and supply chain management is here, and Greenspace Industrial is ready to help you embrace it.