In the fast-paced world of industrial equipment, efficient storage solutions are crucial for maintaining productivity and organization. Energostar, a leading name in the Baltic states known for its assembly and sales of heavy industrial equipment such as electric motors, reducers, and control systems, faced a common challenge in the industry: space management.

With vast amounts of inventory requiring storage, traditional warehouse methods were no longer sufficient. This is where Modula Vertical Lift Modules (VLM) came into play, transforming Energostar’s warehouse capabilities.

The Challenge: Managing Space in a Growing Industry

Energostar’s inventory includes bulky and heavy items that occupy significant space in their warehouses. As the company grew, so did the need for a more efficient storage solution that could handle the sheer volume and weight of their products without compromising on accessibility or safety.

The Solution: Modula Vertical Lift Systems

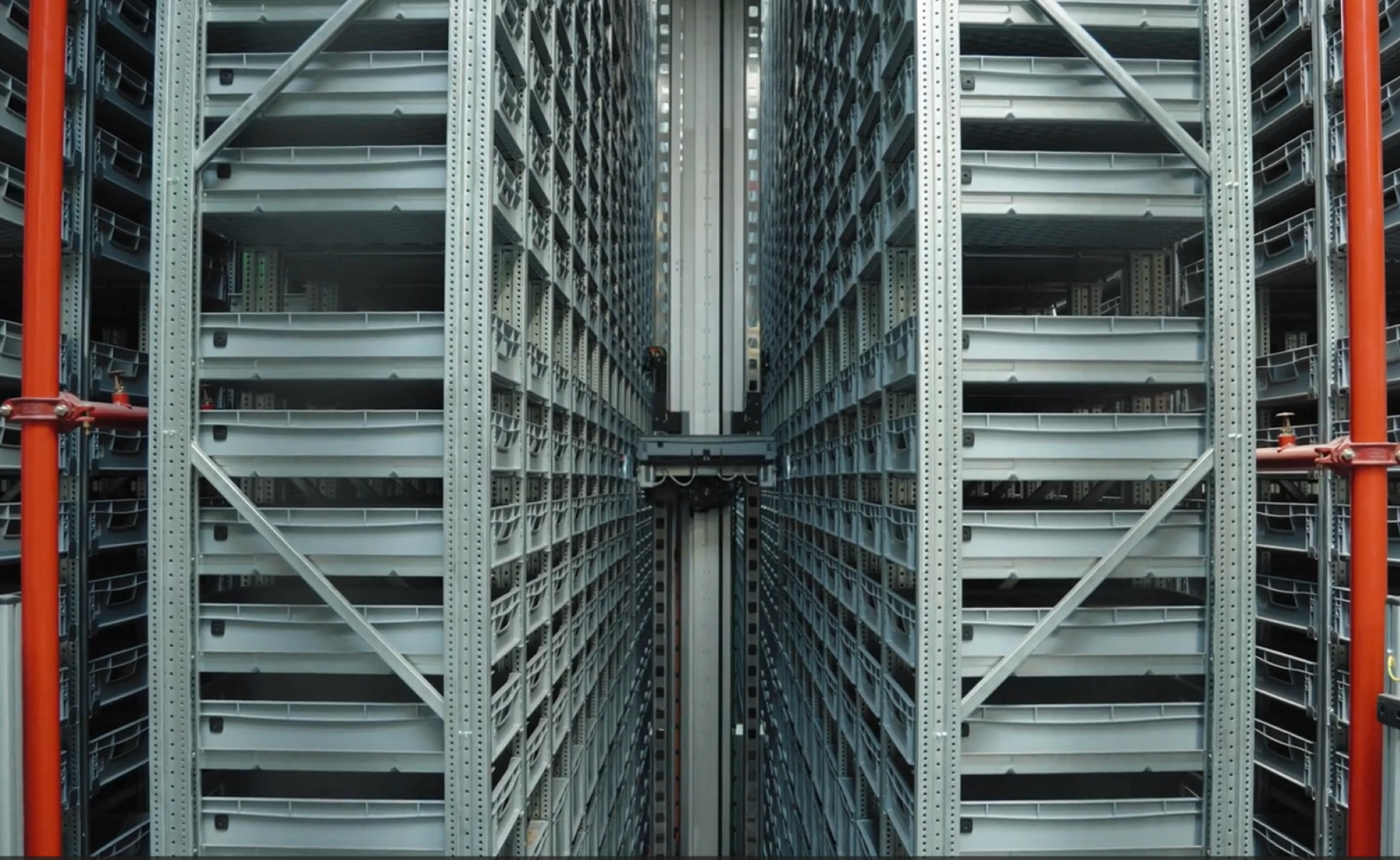

In search of an innovative solution, Energostar found an authorized dealer known for implementing state-of-the-art storage solutions. The choice was clear: Modula Vertical Lift Modules (VLM). These vertical lift systems are designed to maximize storage efficiency by utilizing vertical space, which is often underutilized in traditional warehouses.

Key Features of Modula Vertical Lift Module (VLM):

- High Capacity: Each tray within the Modula VLM can hold up to a remarkable 990 kg, making it ideal for Energostar’s heavy industrial equipment.

- Space Optimization: By building upwards, the vertical lift module significantly reduces the floor space required, allowing Energostar to store more products in less space.

- Improved Accessibility: The automated vertical lift systems ensure that items are easily accessible, reducing the time and labor involved in retrieving products.

The Results: Enhanced Efficiency and Productivity

The implementation of Modula Vertical Lift Modules brought about transformative changes for Energostar. By optimizing vertical space, the company effectively increased its storage capacity without the need for additional square footage. This not only improved their inventory management but also enhanced operational efficiency.

The streamlined storage process reduced retrieval times, allowing Energostar to focus more on their core business activities. Moreover, the robust construction of the Modula Vertical Lift Module ensures the safety and security of the stored items, providing peace of mind to the company.

Conclusion: A New Era of Storage Solutions

Energostar’s experience with Modula Vertical Lift Systems underscores the importance of innovative storage solutions in today’s industrial landscape. By choosing a Modula VLM that accommodates heavy loads and maximizes existing space, companies can not only solve immediate logistical challenges but also prepare for future growth. The success of this case study highlights Modula’s commitment to providing cutting-edge solutions that drive efficiency and productivity in the industrial sector.

For businesses facing similar challenges, Modula Vertical Lift Modules offer a proven path to enhanced warehouse management. As Energostar continues to thrive, their partnership with us and Modula serves as a testament to the power of strategic innovation in overcoming industry hurdles.