In the competitive world of logistics and supply chain management, warehouse optimization is crucial for maintaining efficiency and reducing operational costs. Efficient warehouse operations are the backbone of a successful business, ensuring that products are stored, managed, and dispatched in the most effective manner. At Greenspace Industrial, we specialize in providing advanced solutions for warehouse automation and warehouse space optimization, helping businesses streamline their operations and boost productivity.

What is Warehouse Optimization?

Warehouse optimization involves refining various components of warehouse operations to achieve maximum efficiency and cost-effectiveness. This encompasses space utilization, inventory management, workflow processes, and the integration of advanced technologies. By streamlining these elements, the primary goal is to create a smooth, efficient environment where every aspect of the warehouse functions cohesively. The benefits of warehouse optimization are significant, including increased storage capacity, faster order fulfillment, reduced labor costs, and enhanced customer satisfaction.

Implementing warehouse optimization strategies often involves adopting new technologies and systems that automate and streamline processes. This might include automated storage and retrieval systems (ASRS), warehouse management systems (WMS), and data analytics tools. Additionally, reconfiguring the warehouse layout to improve space utilization and designing workflows that reduce unnecessary movement and bottlenecks are crucial steps. These efforts not only lead to operational efficiencies but also provide a competitive advantage by enabling quicker response times and more accurate order processing.

Warehouse Space Optimization

Maximizing storage capacity is a fundamental aspect of warehouse optimization. One effective strategy is to utilize vertical storage solutions, which can significantly increase the amount of usable space. By installing taller shelving units and leveraging mezzanine floors, businesses can store more products without expanding their physical footprint. Additionally, optimizing aisle width and layout can improve accessibility and workflow, further enhancing space utilization.

Automated Warehouse Systems

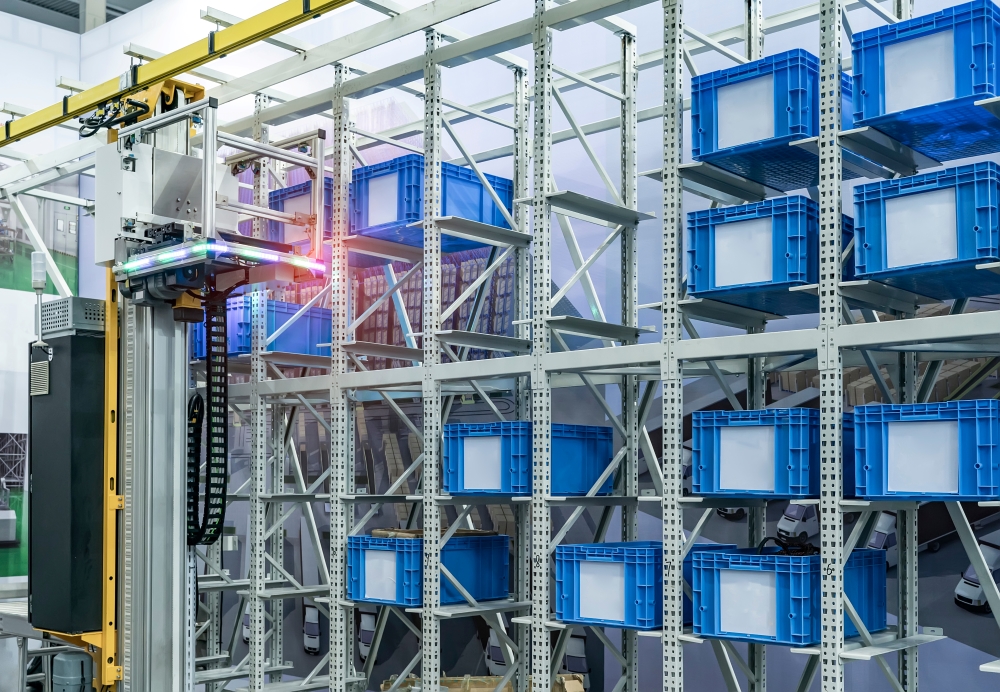

Automation is transforming the warehousing industry, offering solutions that boost efficiency and accuracy. Automated warehouse systems include a range of technologies such as robotics, conveyors, and automated storage and retrieval systems (ASRS). These systems streamline operations by reducing manual labor and minimizing errors. For instance, automated guided vehicles (AGVs) can transport goods within the warehouse, while robotic arms can handle picking and packing tasks.

Warehouse Automation Technologies

Robotics play a pivotal role in modern warehouses. Robots can perform repetitive tasks with precision, reducing the likelihood of errors and increasing throughput. Automated storage and retrieval systems (ASRS) are another key technology, using automated shuttles to retrieve and store items quickly and accurately. These systems can operate in high-density storage environments, maximizing space utilization and improving inventory management.

Inventory Management Techniques

Effective inventory management is crucial for warehouse optimization. Just-in-time inventory (JIT) is a popular method that minimizes stock levels and reduces storage costs by receiving goods only when needed for production or order fulfillment. ABC analysis is another technique that categorizes inventory based on importance, allowing businesses to prioritize high-value items and manage them more efficiently.

Layout Design for Efficiency

The design of a warehouse layout has a significant impact on efficiency. Optimized floor plans ensure that goods flow smoothly from receiving to shipping, reducing bottlenecks and improving productivity. Workflow streamlining involves arranging storage and work areas logically, so that related tasks are located near each other. This minimizes unnecessary movement and enhances overall operational efficiency.

Picking and Packing Optimization

Efficient picking and packing processes are essential for fast order fulfillment. Advanced picking methods, such as zone picking and batch picking, can reduce travel time and increase picking accuracy. Implementing automated packing systems can further enhance efficiency by standardizing packaging processes and reducing the time required to prepare orders for shipment

Labor Management Solutions

Managing the workforce effectively is a key component of warehouse optimization. Workforce planning involves scheduling shifts and tasks to ensure that the right number of employees are available when needed. Providing ongoing training and development helps employees stay proficient in their roles and adapt to new technologies and processes.

Use of Data Analytics

Data analytics is a powerful tool for enhancing warehouse operations. Predictive analytics can forecast demand and optimize inventory levels, while real-time data tracking provides insights into operational performance. By analyzing data, businesses can identify trends, pinpoint inefficiencies, and make informed decisions that improve overall productivity.

Sustainability in Warehousing

Sustainability is becoming increasingly important in the warehousing industry. Green warehousing practices, such as using energy-efficient lighting and equipment, can reduce environmental impact and lower operating costs. Additionally, implementing recycling programs and minimizing waste contributes to a more sustainable operation.

Safety and Compliance

Ensuring safety and compliance is essential for any warehouse. Adhering to safety protocols and regulatory requirements helps prevent accidents and avoids costly fines. Regular safety audits and employee training programs can maintain a safe working environment and ensure compliance with industry standards.

Technology Integration

Integrating technology into warehouse operations can greatly enhance efficiency. The Internet of Things (IoT) allows for real-time tracking of assets and inventory, providing valuable data for decision-making. Integration with enterprise resource planning (ERP) systems ensures that warehouse activities are aligned with overall business operations, improving coordination and communication.

Material Handling with Sortation Systems

Material handling is a critical aspect of warehouse operations, and sortation systems play a vital role in optimizing this process. Sortation systems automate the sorting of products, ensuring that items are directed to the correct locations within the warehouse. This not only speeds up order fulfillment but also reduces the risk of errors. By integrating sortation systems, businesses can achieve greater accuracy and efficiency in their material handling processes.

Moreover, sortation systems can be customized to handle a wide range of products, from small parcels to large pallets. This flexibility makes them an ideal solution for warehouses with diverse inventory. By automating the sorting process, businesses can free up labor resources for other tasks, further enhancing overall productivity.

In conclusion, warehouse optimization is a multifaceted process that involves improving various aspects of warehouse operations to maximize efficiency and minimize costs. From space optimization and automation to inventory management and data analytics, each element plays a crucial role in creating a seamless, efficient warehouse environment. At Greenspace Industrial, we are committed to helping businesses unlock their warehouse potential through innovative solutions and expert guidance.