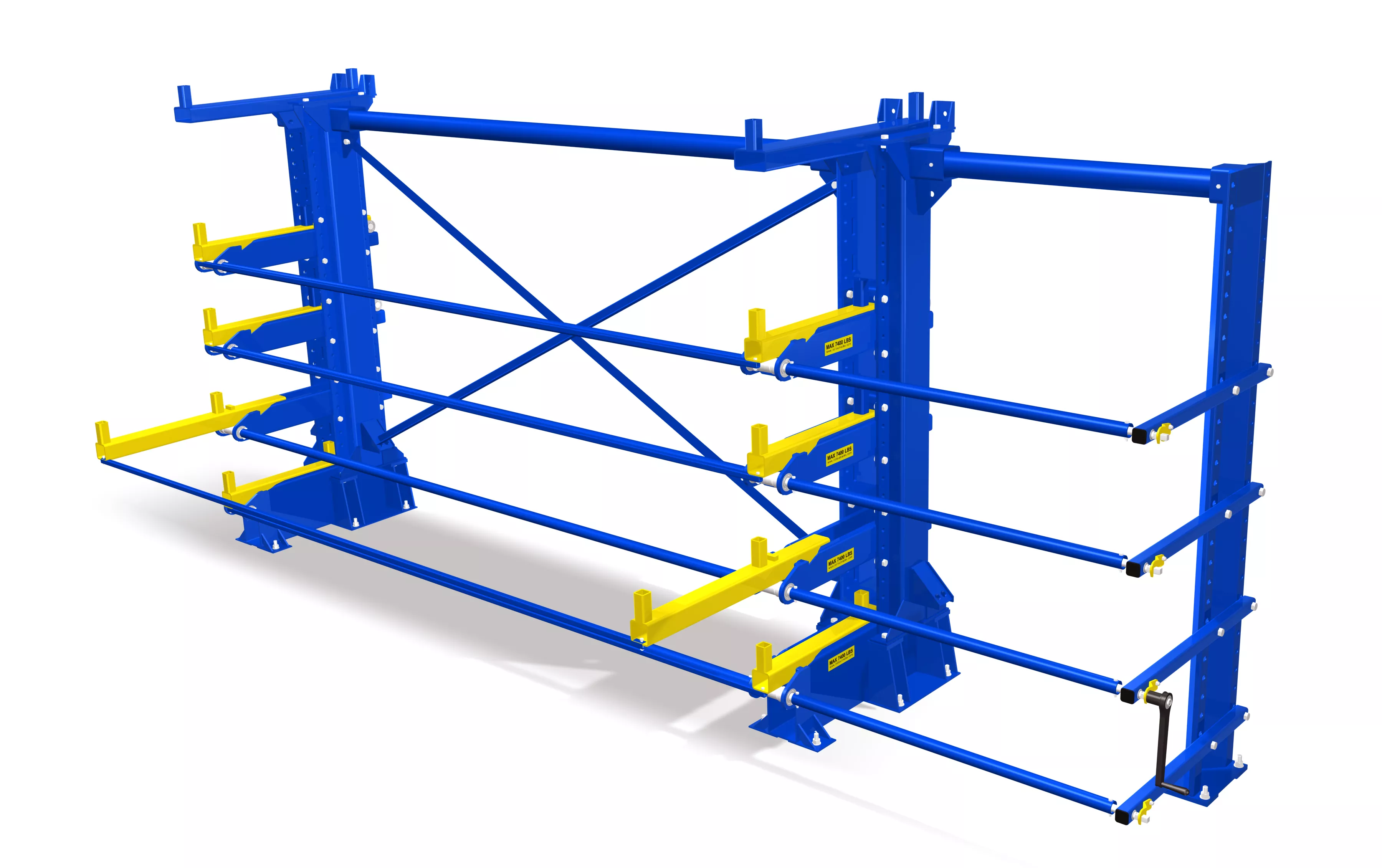

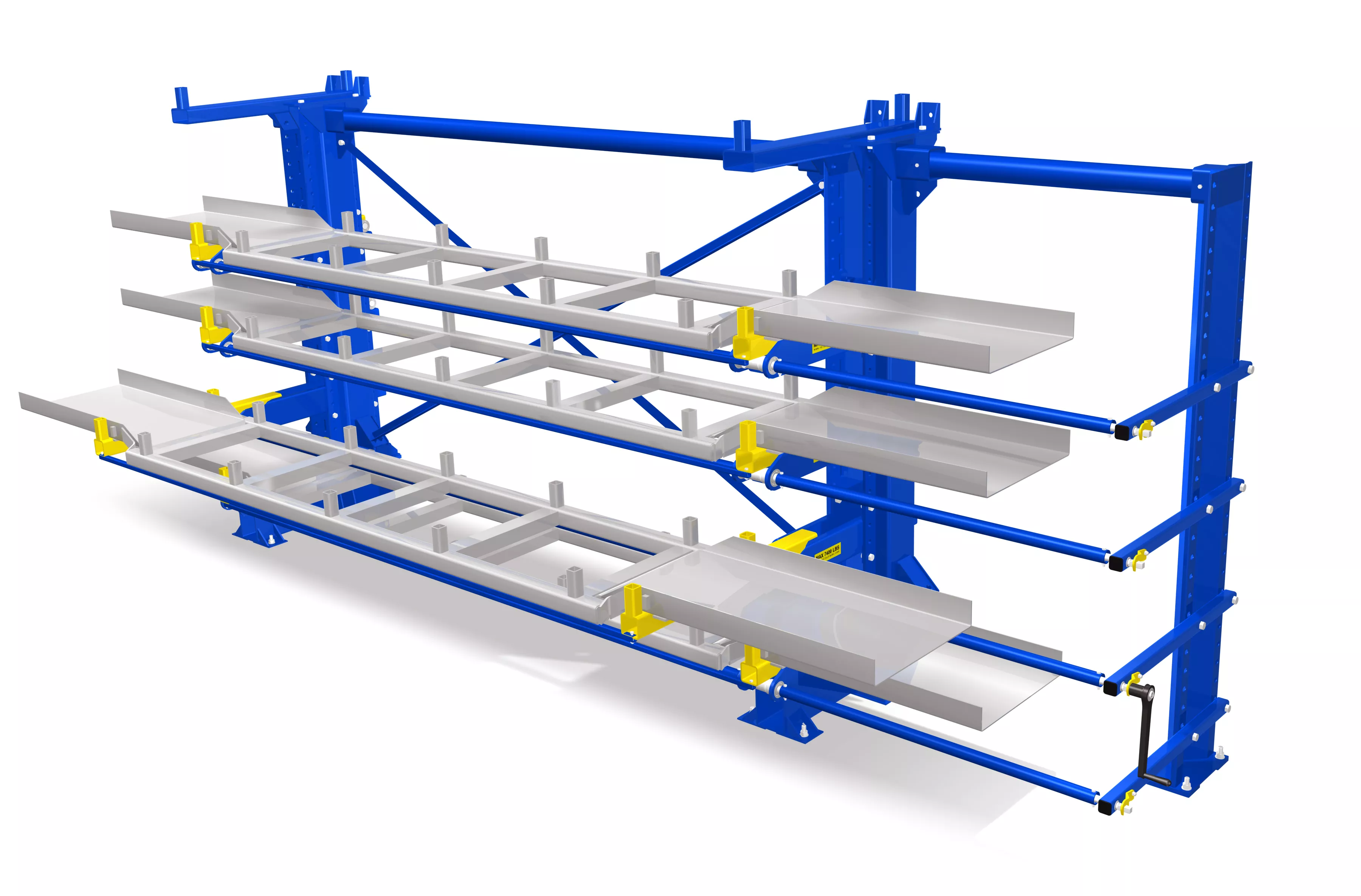

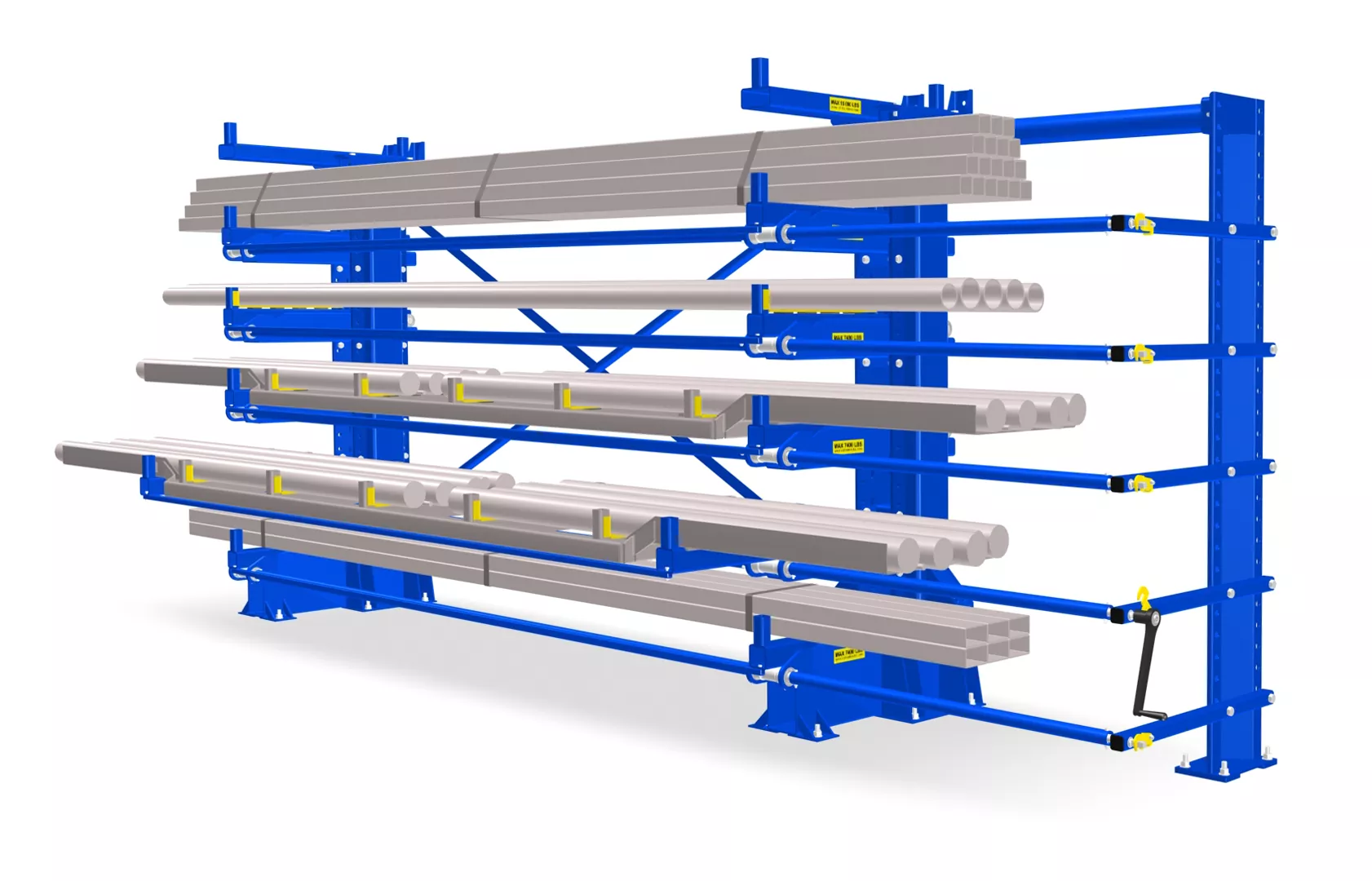

Ergonomic Material Handling with Roll Out Racking

Roll Out Racking systems provide a safe, ergonomic solution for storing and accessing heavy materials, tooling, and equipment. Featuring extendable shelves that slide out smoothly, these racks eliminate the need for forklifts to reach deep into racking rows—enhancing safety, efficiency, and space utilization. Ideal for handling dies, molds, and other heavy parts, roll out racks support improved workflow, reduce injury risks, and optimize warehouse productivity.